“The Intelli-Hood® system at Shriner’s is exceeding expected savings, it has the staff very impressed…which makes us look like heroes! We’re pleased with the data and will get it installed in future kitchens.”

– Mike Sullivan, Hill Mechanical Operations Inc, Director of Facilities for Shriner’s Hospital

CONTEXT

Faced with the industry challenge to reduce operating costs, Shriner’s Hospital sought after promising opportunities to reduce energy usage. Other hospitals in the area had selected Demand Control Kitchen Ventilation (DCKV) for their cafeteria kitchen hoods based on promising estimated savings and available utility incentives. Shriner’s decided to also take advantage of the opportunity.

- Total motor power: 8 HP

- Daily operating hours: 14

- Days per week: 7

- Weeks per year: 52

- Cost per kilowatt hour: $0.10

- Climate zone: 5

RESULTS

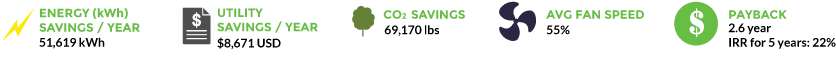

Shriner’s Hospital made use of $4,000 in total incentives from both People’s Gas and Franklin Energy to get DCKV installed. Intelli-Hood® reduced their hood exhaust fan speed by 45 percent and has been proven to perform above expectations.

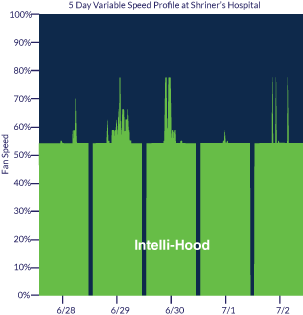

Below is a sample graph of the varying exhaust fan speed for one day at the hospital:

COULD INTELLI-HOOD® BE A FIT FOR MY PROJECT?

Are you curious how much energy Intelli-Hood® could save within your commercial or industrial kitchens? Submit an energy savings estimate request form at the bottom of our Intelli-Hood® page to get started.