CONTEXT

Faced with the industry challenge to reduce operating costs, Gillette Stadium sought after promising opportunities to reduce energy usage. Other stadiums in the country had selected Demand Control Kitchen Ventilation (DCKV) for their kitchen hoods based on promising estimated savings and available utility incentives. The Gillette Stadium team also decided to take advantage of the opportunity.

- Total motor power: 41 HP

- Daily operating hours: 14

- Days per week: 7

- Weeks per year: 50

- Cost per kilowatt hour: $0.10

- Climate zone: Marine

RESULTS

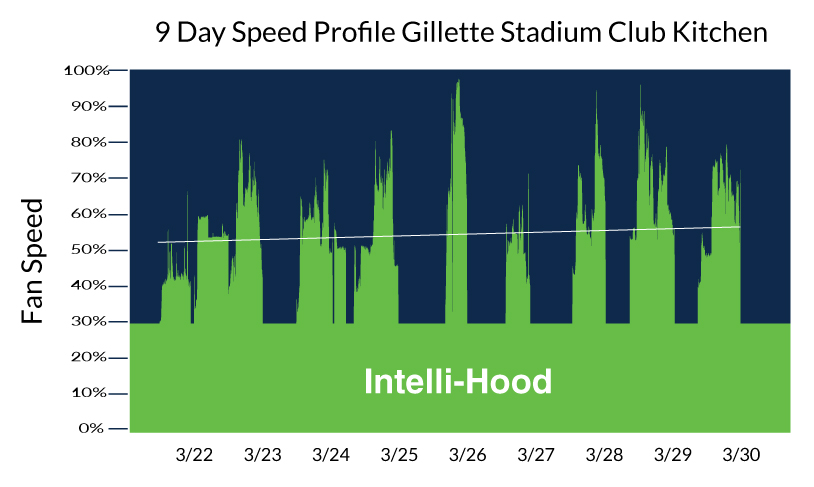

Gillette Stadium selected Intelli-Hood® to be installed into the hoods in the Club and Players kitchens. The team capitalized on utility rebate incentives that expedited the payback projection by 1.5 years. After operating for some time, the two kitchens were tested and proved to have reduced exhaust fan speed dramatically. In the Players kitchen the fan speed was reduced by 66 percent and in the Club kitchen the speed was reduced by 55 percent. Combined, the average fan speed across both kitchens was 60 percent.

Below is a sample graph of the varying exhaust fan speed for one day at the Club Kitchen:

COULD INTELLI-HOOD® BE A FIT FOR MY PROJECT?

Are you curious how much energy Intelli-Hood® could save within your commercial or industrial kitchens? Submit an energy savings estimate request form at the bottom of our Intelli-Hood® page to get started.