CONTEXT

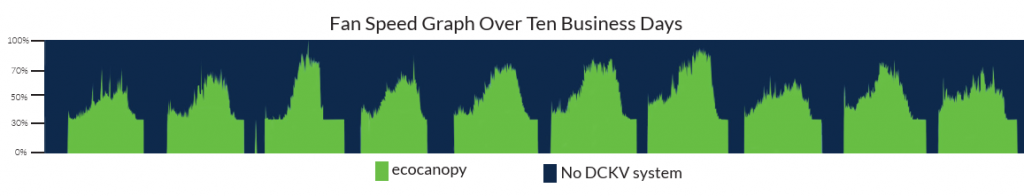

APCO, a local family-owned petrol station, was focused on finding ways to reduce their operating costs and lessen the environmental impact by reducing the amount of fuels being burned to power their locations. They identified their kitchen ventilation as a place of improvement and decided to implement a demand control kitchen ventilation system to self- modulate fan speeds based on cooking activity.

SOLUTION

They chose ecosense powered by Melink Intelli-Hood® because ecosense uses site-specific information combined with performance data from thousands of previously installed systems so system performance can be predicted accurately.

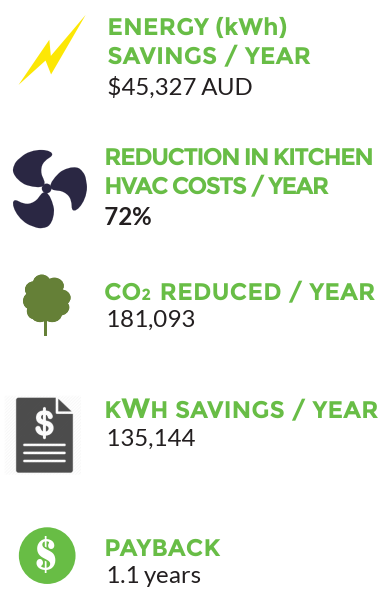

At first, they decided to run a pilot program to verify the system was a good fit. Based on excellent preliminary results they decided to install two more locations and quickly had the same success. In their first year they have saved over $45,000 AUD in energy savings by reducing their kitchen operating costs by 72%, securing their return on investment in just over a year!

or contact us today to learn more about Intelli-Hood® and the benefits of kitchen hood controls.