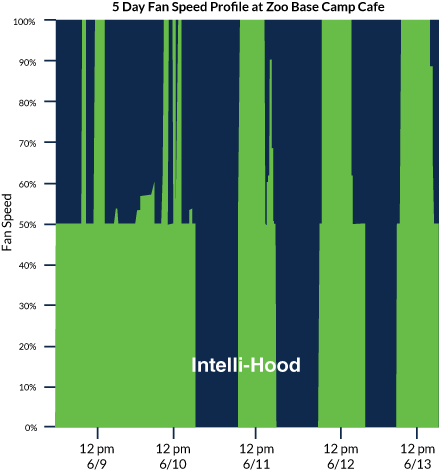

To maintain your kitchen’s system, regular Intelli-Hood cleaning is important. If general cleaning is not performed, the Intelli-Hood® system’s optic sensors can trigger a fault and will operate the fans at 100%, thus eliminating any opportunity for energy savings. Below we will cover tips to clean the temperature sensors, optic sensors, hood exterior, and touchpad.

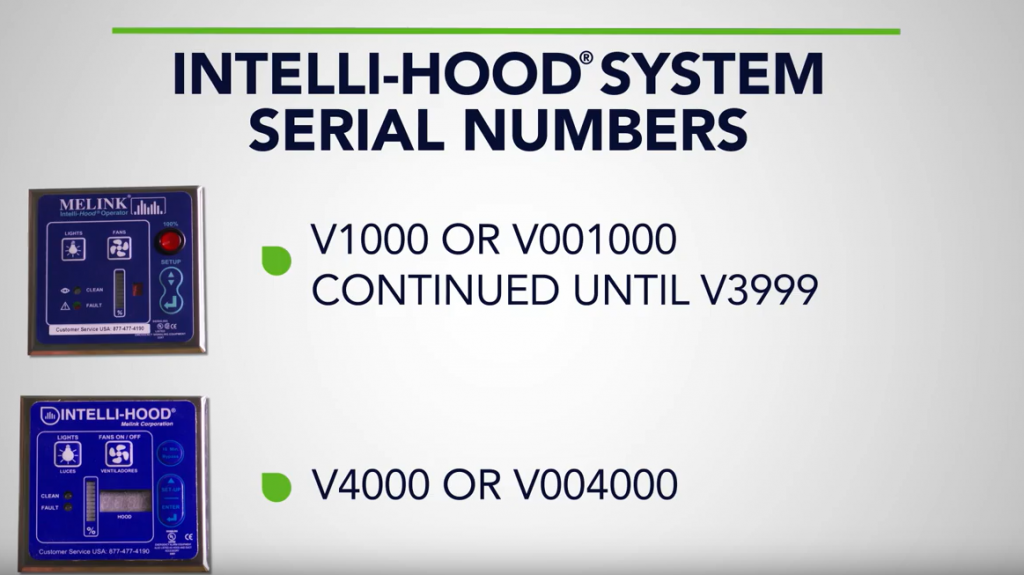

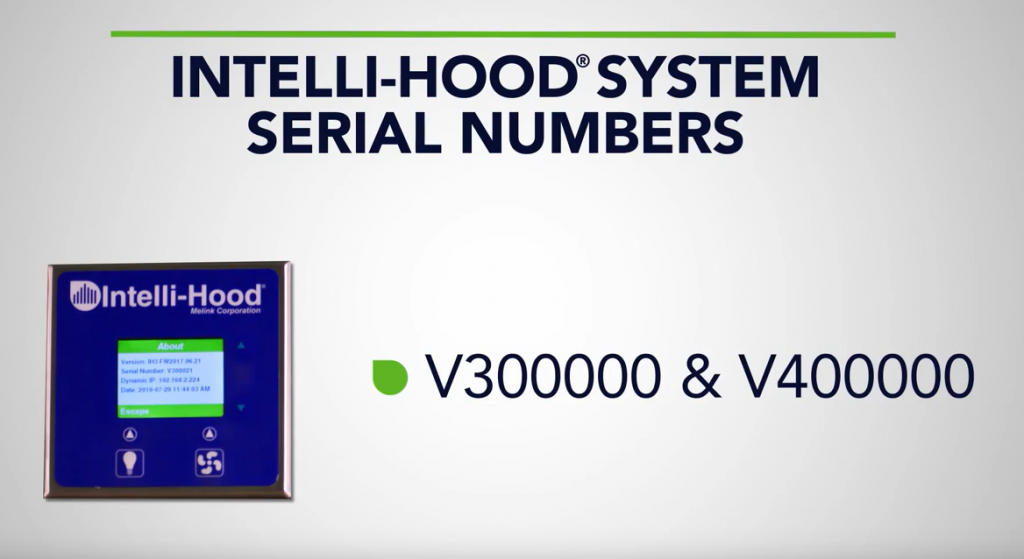

Most system damage is related to improper cleaning. Before any cleaning procedure, it is important to consult your system’s reference guide. The general optic and temperature sensor guidelines below apply to all systems (IH1, IH2, IH3).

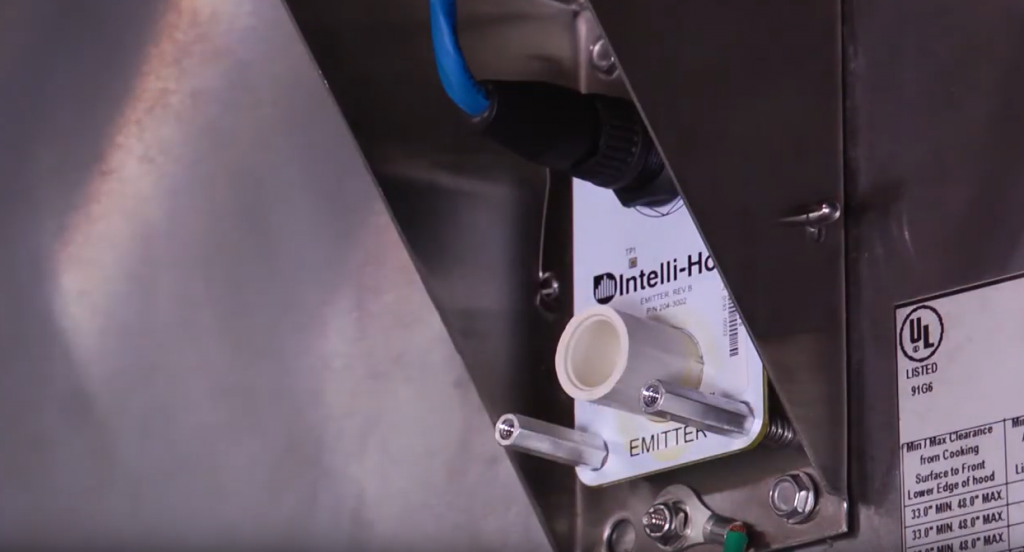

Cleaning the Optic Sensors

The most common Intelli-Hood cleaning issue is owners not taking proper precautions to protect the optic sensors. Each set of optics has an emitter and a receiver; these pieces have a resilience coating to protect them from general moisture. For Intelli-Hood to function properly, site staff needs to keep the optics clear of obstructions and clean the optic sensors periodically with non-abrasive, non-corrosive cleaning products. We recommend only using a mild cleaning detergent, such as Dawn dishsoap.

How often should I clean? The time between cleanings is largely dependent on the volume of grease being exhausted. Optic sensors in kitchens with lots of grease-cooking may need to be cleaned several times a month. On the other hand, some kitchens may have sensors that can go several months between cleanings. If sensors get too much build-up on the lenses, an optic fault will occur. The fans will run at full speed until the sensors are cleaned and reset.

How should I clean the optic sensors? Press the push-button latches on the sides of the optic box to remove the cover. Then wipe the lens of the optic circuit board with a soft, damp cloth. Replace the cover of the optic box ensuring that the green cable connecting the cover to the optic bracket is not in front of the lens.

Is hood cleaning safe? When performing a general cleaning of the kitchen hood, hood cleaners must be careful to keep the Intelli-Hood components dry. The optic sensors are water-resistant but not waterproof. The optic box should be sealed with thick tape and plastic wrap before using high pressure water, steam, or other cleaning chemicals in the hood. Hood cleaners should not soak any parts of the system. Harsh cleaning chemicals can lead to scratching of the optic lens. Care should be taken around the fire suppression device (ANSUL pipes) when cleaning; sometimes when cleaning, these can shift the placement of the optic sensors.

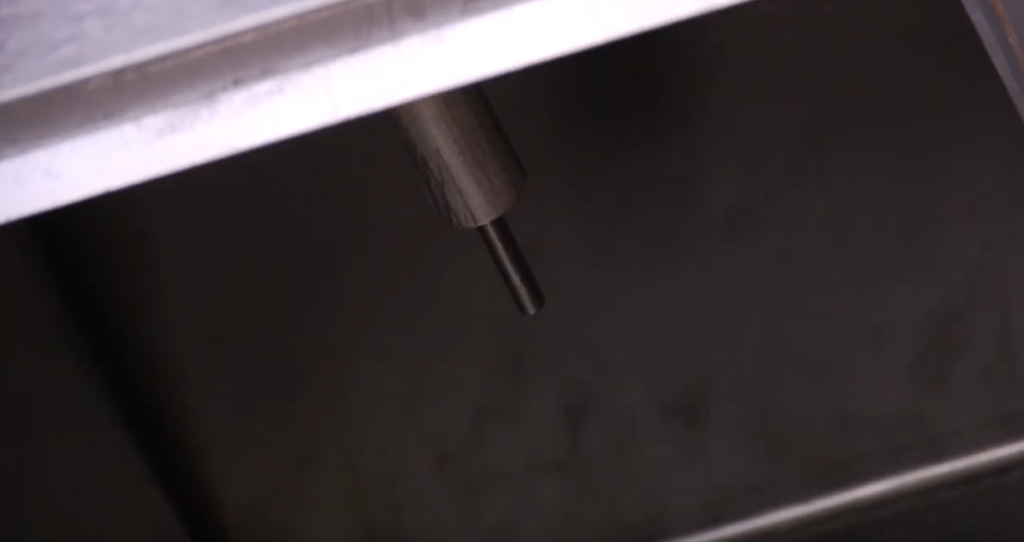

Cleaning the Temperature Sensors

Temperature sensors are encased by a round cylinder to help prevent contaminant buildup on the sensor itself. They rarely need to be cleaned.

However, if extremely large amounts of grease or other contamination build up on the sensor, the probes should be brushed or wiped clean with a soft cloth. Do not wipe down the temperature sensors with force; it is not necessary for them to be absolutely spotless.

Pressure cleaning is not recommended. If water soaks the temperature sensors, the water will work its way back through the threads, reaching the center of the Intelli-Hood processor.

Cleaning Intelli-Hood’s Electrical Components

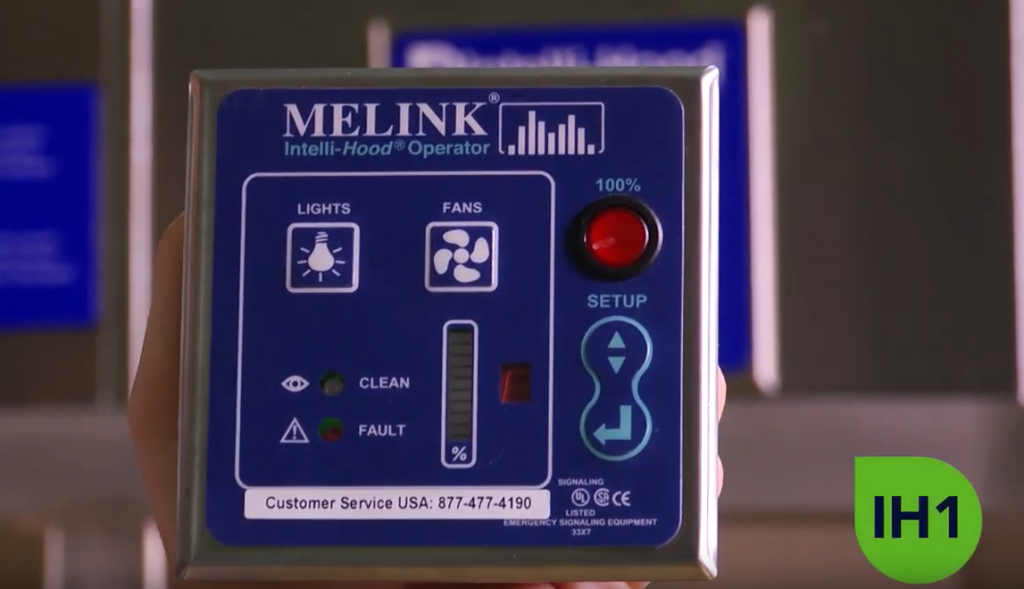

Touchpad: The touchpad may be wiped clean, but it should not be soaked with excessive water. If the face is damaged, special care must be taken to prevent water from getting through the label to the electronic components behind the face.

If holes start to wear in the touchpad’s keypad, contact Melink for replacement parts. You may need to replace the labels or the entire touchpad, depending on the damage. If you do not fix the holes, the internal parts may get wet, eventually leading to system failure and kitchen downtime.

If a touchpad is replaced, caulk should be used to seal the backside. This sealant will help protect the touchpad from kitchen cleaners that are sprayed in its vicinity.

Hood Light Fixtures: The hood light fixtures must be kept dry, too. If water gets inside a light fixture, it could create a short on the circuit and damage the Intelli-Hood processor, which powers the lights.

End Cabinet: If an end cabinet is present, take care to avoid getting components on the inside wet. Generally, these cabinets are completely open from the top.

Cleaning the Hood-Top Equipment

On top of the hood, you may find a number of Intelli-Hood components including the air purge unit, hood controllers, temperature probes, and control cables. These components must remain dry.

If a hood cleaner or anyone else needs to be on top of the hood for any reason, they must be careful to avoid stepping on these components in order to keep them dry.

Access Intelli-Hood reference materials, FAQs, and how-to videos. For advanced troubleshooting, contact Melink Technical Support (available 24 hours a day, 7 days a week) via web request or by calling 877-477-4190.