The Holidays are upon us, with all the excitement and the parties. As the Grinch says, “And Then! Oh, the noise! Noise! Noise! Noise! There’s one thing I hate! All the NOISE! NOISE! NOISE! NOISE!”

Now, I am no Grinch about the holidays, but prior to my tenure here at Melink I worked for nearly 10 years as an Environmental Health and Safety Manager within a large chemical facility, and there were various work areas which exceeded noise thresholds requiring hearing protection. It was LOUD. This is where I became cognoscente of NIOSH (National Institute for Occupational Safety and Health) standards for hearing conservation,

NIOSH states continued exposure to noise above 85 dBA (adjusted decibels) over time will cause hearing loss. The volume (dBA) and the length of exposure to the sound will tell you how harmful the noise is. In general, the louder the noise, the less time required before hearing loss will occur. According to the NIOSH, the maximum exposure time at 85 dBA is eight hours.

Although we may not be able to control the noise of the holiday party or the loud toys the children will receive on Christmas day, perhaps within the working environments of commercial kitchens we can make drastic improvements and reduce the overall noise level.

Studies have been conducted over the years and dependent on many variables such as the size of the kitchen spaces, the duration of peak activity, and other various factors the overall noise level at times approach or exceed the 85dBA level, sources show a typical restaurant operates at 80 dB, although this value does not trigger hearing protection, some restaurants are known to reach 110 dB at times which is the noise level of a jackhammer! Think of the last time you were at your favorite restaurant and seated near the kitchen entrance versus the opposite side of the room.

Demand control kitchen ventilation can help not just provide energy savings but also reduce the noise levels drastically, especially over an 8-hour timeframe for employees in the kitchen spaces. When researching kitchen exhaust fans one will find that the noise levels are reported as a “sone” which depending on the static pressure of the design the noise levels can vary. A sone is a unit of loudness, how loud a sound is perceived. Doubling the perceived loudness doubles the sone value. Within fan specs of kitchen exhaust fans manufacturers indicate the “Sones” level for example a 5hp kitchen exhaust fan has a sone level ranging from 16.5 to 26 sones dependent on duct design. Per the decibel level and sones conversion chart this is equivalent to around 68.3 to 74.9 dB!

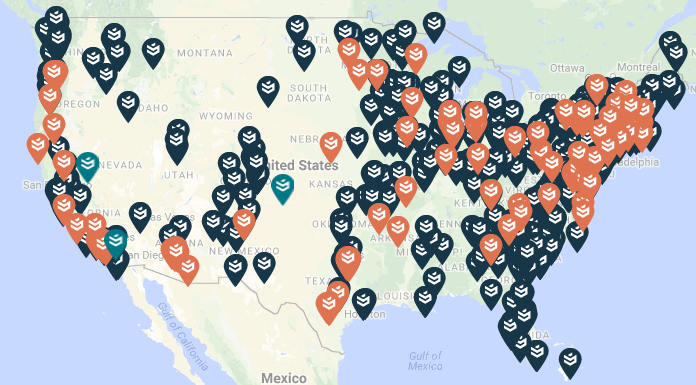

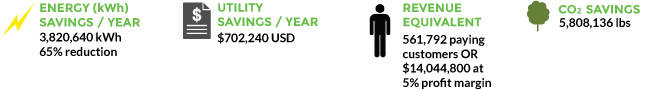

Now considering utilizing a temperature and optic based demand control kitchen ventilation, such as Intelli-Hood, can reduce fan speeds by 30-45% average fan speed over a 24hr period consider the reduction of noise exposure this provides. It is not uncommon for customers post installation of a Melink Intelli-Hood system to recognize significant noise reduction, many times commenting that during food prep hours, although the fans are “turned on” they operate at a minimum speed and it sounds like they are not even operating!

Perhaps you are in a position of influence of the decision to retrofit Demand Control Kitchen Ventilation, or perhaps evaluating and analyzing the opportunity for a client. Remember that there is more savings than simply energy that can be considered when evaluating demand control kitchen ventilation.