HVAC system testing, adjusting, and balancing (TAB) is one of the most misunderstood trades. In spite of its 50-year history, many contractors believe to do TAB, technicians simply need to show up with a flow hood, read grilles, hand over a piece of paper, and ask to be paid thousands of dollars. There happens to be a bit more to it than that.

Among the complexities of the trade, the final TAB report is perhaps the most critical and most misunderstood. When the painters are done, the walls change color. When electricians are done, the

lights come on. When the HVAC technicians are done, the building heats and cools. When the TAB professional is done, he or she simply hands over paperwork and the other trades and owners simply must take their word for it. That paperwork is the TAB firm’s final product and should be professional, complete, concise, and as useful as possible for the end user.

Whether that end user is a design professional, facilities manager, property owner, municipal inspector, or other concerned party, the TAB report should be written and compiled in such a way that even a layman can identify any issues that potentially impact building performance.

There are five elements that any should be consistent in any TAB report:

- Overall professionalism

- Certification

- Remarks and deficiencies

- Discrepancies between design values and actual data

- Mechanical drawings and floor plans

Overall professionalism speaks for itself. Are the numbers hand-scrawled on a piece of paper or is the TAB report well-presented and organized? Does it appear to be a document reflecting the skills and expertise of the industry veteran who produced it? Basic elements that should be included in a professional report include: an executive summary / general remarks, distribution list, table of contents, symbols and abbreviations, as well as corresponding mechanical drawings and certification.

In today’s litigious society, I’ve had more than half a dozen of my TAB reports subpoenaed in legal proceedings. Every TAB report I compile is issued with the mindset that it may end up in the hands of a jury selected from a variety of backgrounds and be examined by professional witnesses who will scrutinize it’s

content. Once that standard is achieved, the report should be able to be tell the overall story in a way that virtually ANYONE can understand, regardless of background.

Certification is a critical element of any TAB report. Sure, there are many incredibly capable technicians out there who operate without certification. However, certification ensures that the

professionals who compiled the report are vetted, tested, and properly equipped to perform the work. Certification also ensures that the TAB firm and TAB professional are current to their certifying

organizations’ standards. Finally, certification provides recourse to the end user should there be issues with the TAB report or work performed by the TAB contractors.

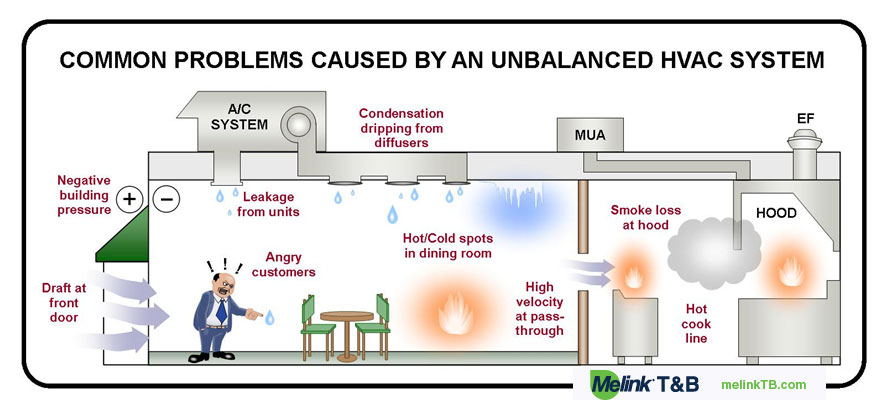

Remarks and deficiencies are very often overlooked. The professional TAB report should have both an executive summary / general remarks section up front to explain overall conditions and issues. If applicable, the summary should be followed by an itemized list of items that remain to be corrected. There is a growing trend to include pictures of deficiencies as well. Often such deficiencies are corrected during the course of the test and balance work and by the time the final TAB report is issued, there are no remaining issues. If that is the case, there should still be general remarks explaining the scope of work and conditions at times of testing.

Discrepancies between design values and actual data collected. The actual test data can be confusing and tedious. Especially reports containing hundreds of pages of numbers and readings. Even to the well-trained eye, reviewing a TAB report can be like trying to read the streaming code in the Matrix movies. However, anyone can read “percentage of design” and determine that any item not within +/- 10% or (5% in some cases) needs further review. ANY item not within design tolerances should be accompanied by a remark explaining why. The remarks should also explain what corrective action can be taken, or if a corrective action is even needed. Again, this can be a critical part of the report that should be written to stand out, even to the layman, without being overly technical or confusing.

Finally, let’s talk about mechanical drawings and floor plans. I have the great fortune of providing training to professionals from all over the world. These professionals come from a wide variety of backgrounds. The number one complaint I hear from design professionals and facilities managers is that many TAB reports are missing floor plans / mechanical drawings that correspond to the reported data. This is the number one item in any TAB report that makes the report practical and functional to the end user.

There are many instances where plans are not provided to the TAB contractor, or cannot be removed from a facility. There are many options around these situations. From a simple, hand-drawn

ceiling plan indicating supply, return, and exhaust diffusers, to taking a picture of the immovable plans and numbering the inlets, outlets, and equipment. You can use a CAD program, or even something as simple as PowerPoint to provide a visual reference. Regardless of how this is accomplished, these numbered plans and/or drawings are the glue that bind the TAB report together, and MUST be included.

The TAB report is a critical element of the construction process that assures the design team’s intent was met. It also assures the building owner that they have the systems they paid for.

The TAB report should reflect the professionalism and skills of the technicians who provided the work behind it and who ultimately compiled and published it. However, it is a meaningless collection of data if it is not reviewed, understood, and used.