Believe.

Every building has the power to change the world.

Creating Energy Efficiency for Commercial Buildings.

250+

Unique Customers

150K

Sites Serviced

40K

Hoods Controlled

Melink Services

Where systems meet certainty.

Ensure your buildings are healthy, energy-efficient and comfortable with HVAC Test, Adjust and Balance and Building Commissioning services. Let Melink help assess your HVAC systems to promote optimal energy utilization and peak performance.

Test, Adjust & Balance (TAB)

Independent verification of HVAC system integrity.

Intelli-Hood® Kitchen Ventilation

Put energy savings on auto-pilot.

Melink, the industry leader in DCKV and creator of Intelli-Hood. Patented Intelli-Hood Kitchen Ventilation Controls automatically adjust to your cooking activity so you don’t waste energy and conditioned air.

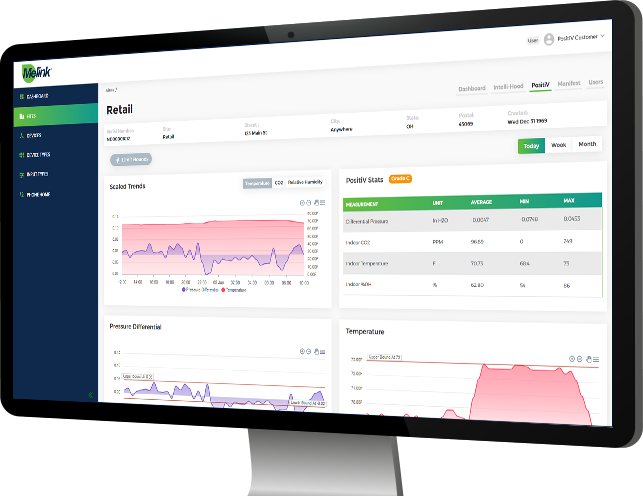

Positiv Building Health Monitor

Keep a pulse on your HVAC's health.

A patent-pending standalone system, PositiV monitors building pressure and indoor air quality, remotely tracking HVAC health, reducing energy usage and improving energy efficiency. Monitor the slightest changes in your commercial building.