A recent study by The National Veterinary School of Toulouse in France revealed that mycotoxins can be inhaled and should be investigated as parameters of indoor air quality. This means that food fungus formerly thought to have no effect on air quality can actually become airborne and dangerous to building occupants. The results were published in Applied and Environmental Microbiology, which is the American Society for Microbiology’s journal.

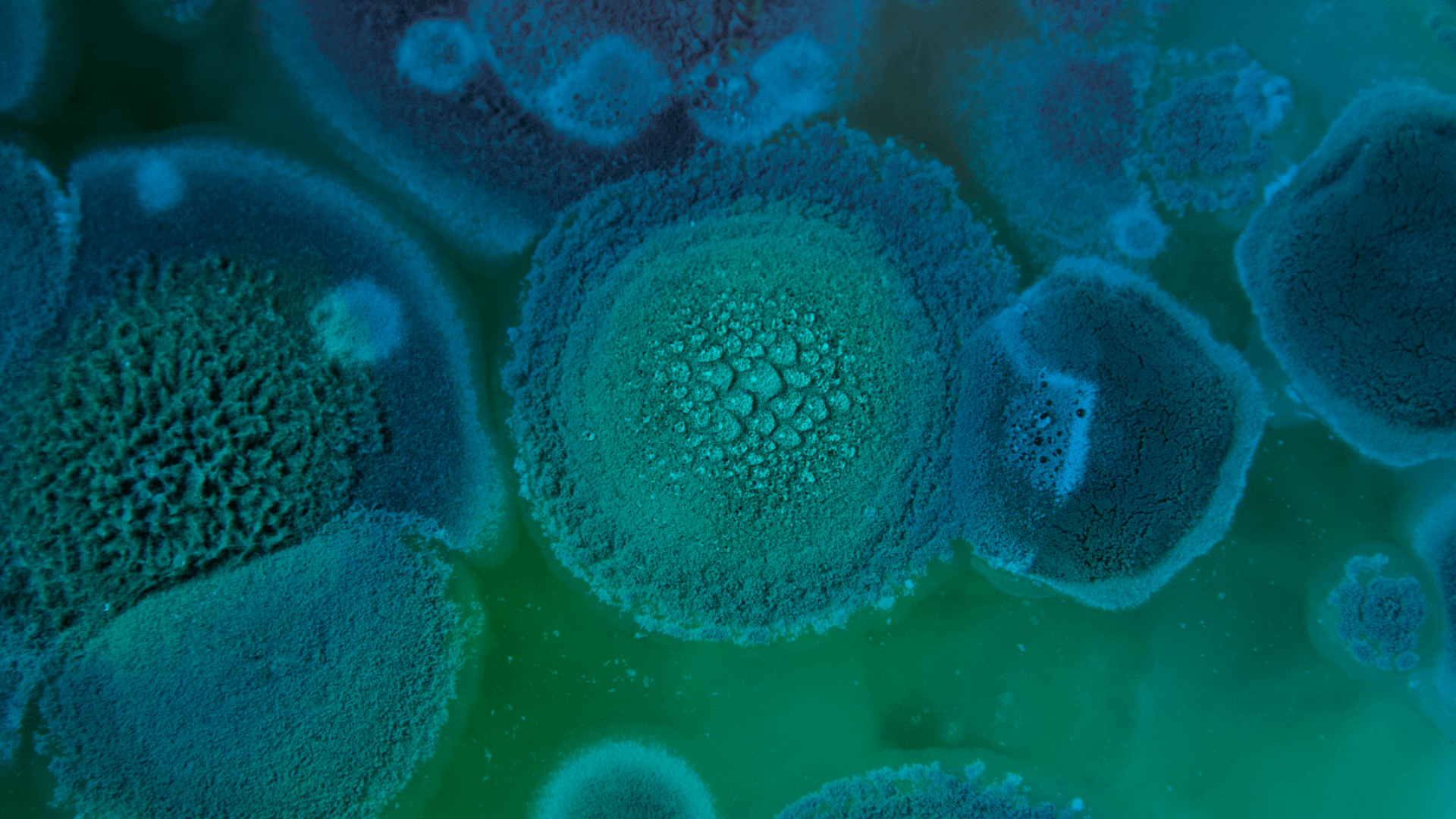

The researchers were interested in the fact that far less research exists on the dangers of airborne fungal toxins compared to fungal toxins in foods. The research team focused on three fungi commonly found in contaminated food: Penicillium brevicompactum, Aspergillus versicolor and Stachybortys chartarum. The research team conducted this study by creating a flowing stream of air over a piece of wallpaper contaminated with the three fungi and then analyzing the samples of air.

The results showed some toxins from the contaminated wallpaper were present on tiny particles of dust that were considered to be easily inhalable. If you own a restaurant, hotel, retail location or supermarket, these results should be eye-opening. These findings should amplify the importance of performing regularly scheduled HVAC test and balance services to ensure your HVAC system is operating as designed, and not contributing to organic growth.

As a business owner, it’s extremely important to make sure that your building’s HVAC system is working properly, not only for health reasons like the airborne fungus we specified above, but for first impressions of new customers. An unbalanced HVAC system may cause humidity problems, and this may result in fogged over windows in the morning, which prevents customers from being able to see inside. Poor air pressure can even make it difficult to open doors.

An unbalanced HVAC system can also result in uncomfortable temperatures and humidity that does damage to ceiling tiles and creates slippery floors which can become both a safety issue and legal liability. In kitchen environments, an unbalanced HVAC system can also cause smoke and odors to flow past the hood and seep into the dining area.

Here at Melink we provide HVAC test and balance services, HVAC commissioning, indoor air quality tests and water balancing services that will help to alert you to dangerous conditions within your building.

Our 100 percent self-performing network of technicians ensure consistency across your locations. Mechanical systems fall out of alignment over time, you should keep your HVAC at peak performance by rebalancing it every three to five years. We also offer comfort investigations that can be conducted after HVAC complaints or negative building pressure issues.

Many of the largest chains in the US recommend Melink because of the convenience, consistency and cost effectiveness of our service. They also know that our reputation for integrity, quality and service is proven. As we’ve demonstrated, not only can overlooking the air quality of your building be dangerous for the health of the building’s occupants, but it can also cause a business owner to lose customers. In order to best help business owners decide if it may be time for an HVAC Test and Balance service, we’ve provided these questions to ask yourself:

Is there a draft at the front door of my building?

Is there leakage from units in the ceiling?

Is there condensation dripping from diffusers?

Are there noticeable hot and cold spots?

If you answered yes to any of these question, you are likely due for some servicing. Reach out to us today to improve the conditions of your building and increase the quality of your business!