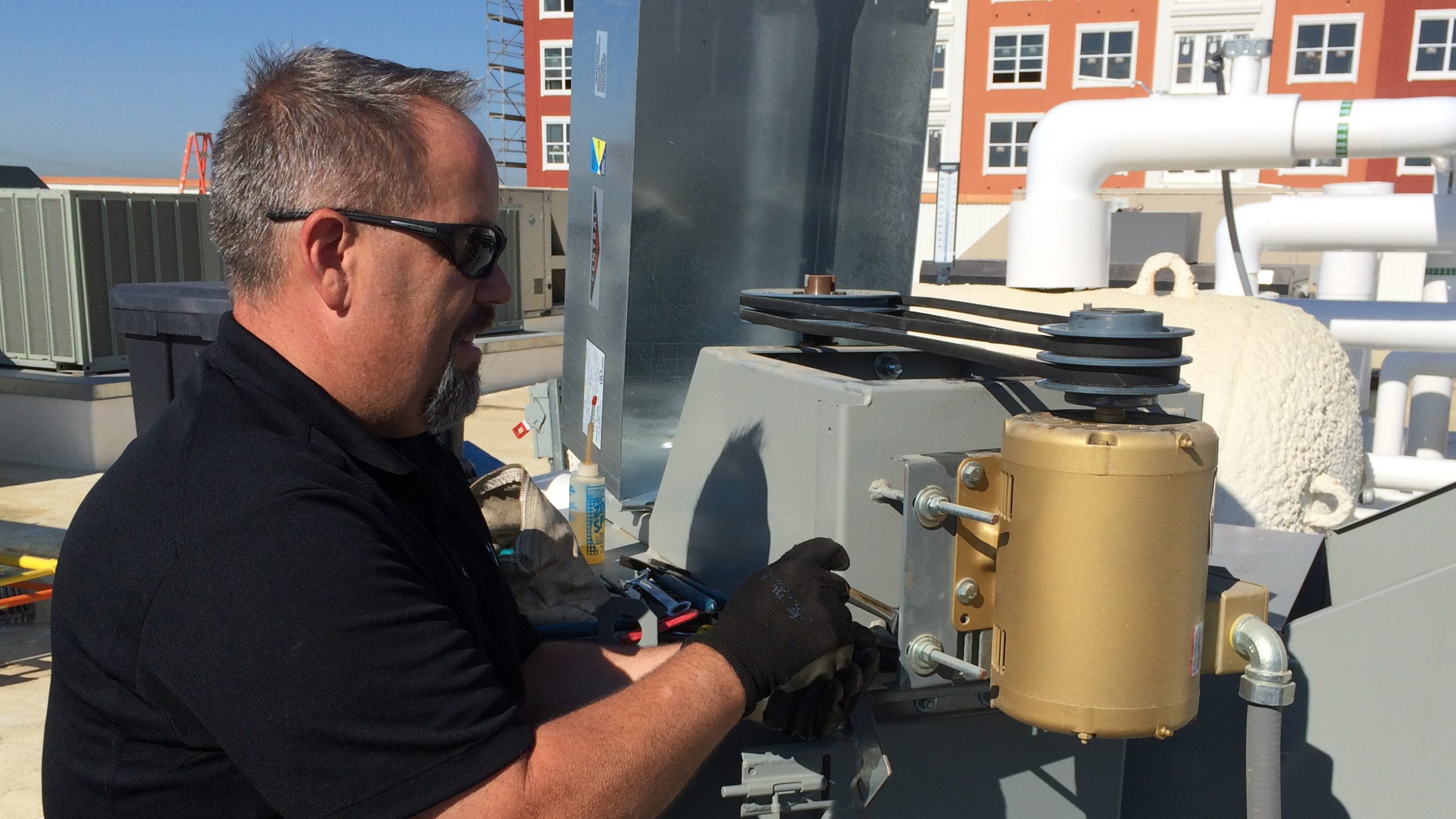

Are you still experiencing HVAC comfort or efficiency problems? It’s time for the next level of technical HVAC skill. Though at this point you may have realized you’re dealing with negative building pressure, you might wait on calling the air balance contractor and first become more informed about the problem with your management team. It’s time to call in your trusted mechanical contractor (MC).

Your contractor’s first steps will be to inspect many of the same areas we advised in our previous post. These areas should include circuit breakers, thermostats, as well as the areas listed below. In addition, you should locate any past air balance reports and confirm that all the punch list items were corrected. With these observations and baseline data as your starting point, you or your MC can begin to formulate a hypothesis. To dig deeper into problems, check the following areas where we most frequently find the causes of HVAC comfort issues:

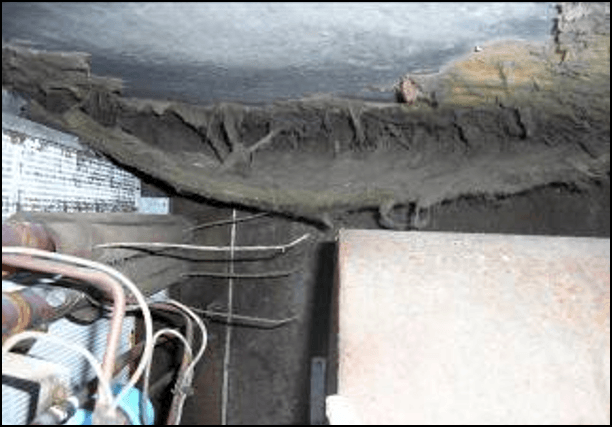

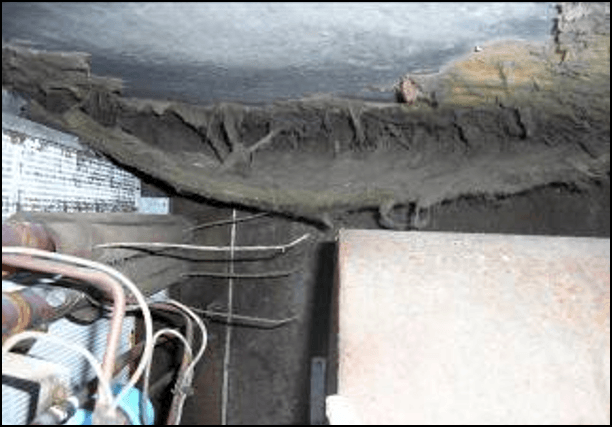

1. Filters inside the unit

Dirty, old, or clogged filters will restrict airflow through the unit. Filters should be at least replaced quarterly for a commercial unit and can be added as part of a preventative maintenance scope of work. In the Restaurant Facility Management Association’s Facilitator Magazine, Red Lobster Facility Manager Angela Hughes writes in her article Staying On Top of Comfort Concerns, “The washable metal filters inside each makeup air fan need to be cleaned during major preventative maintenance. These are often overlooked by HVAC preventative maintenance vendors. Dirty filters can block airflow into the unit and greatly affect the building balance. If the filters are damaged or missing, be sure to replace them.”

| Above: Dirty Outdoor Filters |

2. Inspect coils inside units

Dirty, clogged, or frozen coils can also heavily restrict airflow through the unit. Mechanical contractors are equipped to unfreeze and clean coils. Angela Hughes explains, “Dirty coils will cause the unit to freeze up and temporarily shut down, which causes stress on the compressors.” Further, if the rooftop unit (RTU) blower compartment and/or coils are dirty, then they are likely causing reduced airflow and contaminated air. The solution is to clean internal components of the RTU.

|

Above: Frozen Evaporator Coil

|

|

| Above: Dirty Rooftop Unit Blower Compartment |

|

|

| Above: Dirty blower wheel inside Rooftop Unit |

3. Check refrigerant levels

Low refrigerant levels can lead to uncomfortably warm temperatures. Your mechanical contractor should be equipped to refill refrigerant.

4. Open up units and inspect outside air dampers

The amount of outside air is specified in the building’s design, however it is often adjusted later as a quick-fix for short term issues, leading to bigger problems in the long run. It is common to find improperly installed and inoperable outdoor air dampers, which negatively impact the building pressure. The dampers will need to be adjusted to proper position and outside air intakes may also need to be installed to achieve desired airflow.

|

|

|

Above: Improperly Installed Outside Air Dampers (sealed closed with caulk)

|

5. Check for negative building pressure in your facility

The tell-tale sign of negative building pressure can be found with using the door test. A quick way of checking your building’s air pressure is to test it with a lighter or a match at an exterior door. Crack the door open and place a lighter in the crack as pictured below. If the flame pulls toward the inside of building, then the building is negative.

|

Above: If flame pulls toward inside of building, the building is negative.

|

6. Has your facility undergone a remodel, renovation, or a major change in equipment?

Remodels, renovations, or major equipment replacements change the distribution of airflow and requires an air balance service. HVAC equipment installed in a building will not function at design specification at start up. Adjusting the system to design specification requires testing, adjusting, and balancing.

These are 6 examples of what your mechanical contractor may discover in their assessment process. If they are able to find and properly resolve the HVAC comfort or efficiency issues, then your troubleshooting may end here. If not, you may need to consider calling in a certified test and balancing firm. See our next post in this series for understanding what to look for in a test & balance contractor.

Additional Reading:

- Bringing in an Air Balance Contractor, Larry Moore, Melink Test & Balance

- Angela Hughes, a Red Lobster Facilities Manager with distinguished technical knowledge of HVAC systems, authored a very practical approach for FMs to self-diagnose comfort problems without prematurely spending money on contractors. Staying On Top Of Comfort Concerns

- For suggestions on preparing for an air balance, read Optimizing Air Balance Report Data by Greg DuChane, Retail-Restaurant Vertical Market Director at Trane

Resources:

DuChane, Greg. “Optimizing Air Balance Report Data.” Trane Tracks (Apr. 2015): n. pag. Trane. Web.

Hughes, Angela. “Staying On Top Of Comfort Concerns.” Facilitator Magazine Apr/May (2015): 66. Restaurant Facilities Management Association, 25 June 2015. Web. 26 Aug. 2015.

Melink Test & Balance Technicians. HVAC Deficiency Images. Digital image.Melink Test & Balance. Melink Corporation, n.d. Web. 26 Aug. 2015. .