Overview

The upscale Radisson Blu hotel, situated on Yas Island in Abu Dhabi, encountered a dilemma involving rising utility expenses within its commercial kitchens. In response, the hotel opted to address this concern by installing Intelli-Hood’s Demand Control Kitchen Ventilation (DCKV) system. Intelli-Hood employs dual sensing smart technology to optimize kitchen ventilation, reduce energy waste, and elevate operational efficiency.

Performance

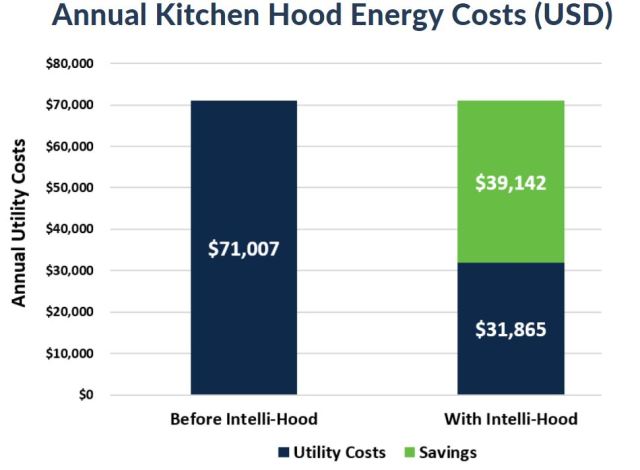

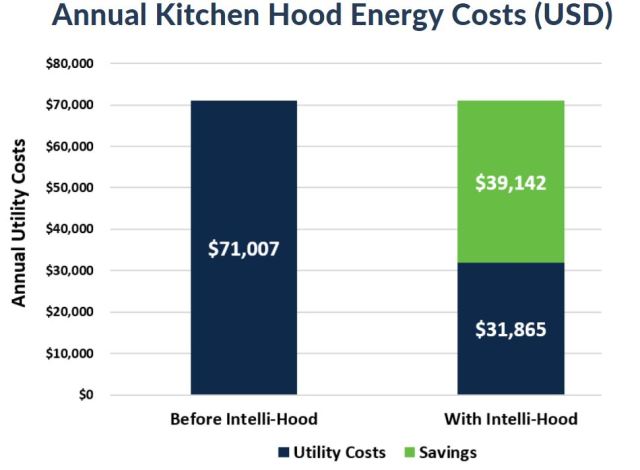

Before adopting Intelli-Hood’s DCKV controls, Radisson Blu faced substantial utility expenses, amounting to a significant annual expenditure of $71,007 for its kitchens. This financial challenge prompted the hotel to invest in Intelli-Hood’s DCKV system to lower utility costs and improve operational efficiency. Renowned as the industry leader in optimizing kitchen ventilation based on real cooking activities, this system aids in reducing energy usage and operational expenses.

The integration of Intelli-Hood® into all commercial kitchens at Radisson Blu – Abu Dhabi was conducted smoothly, ensuring minimal disruption to the hotel’s daily operations. The completed process produced notable efficiency and performance outcomes.

After implementing Intelli-Hood®, the hotel realized substantial annual utility cost savings, amounting to $39,142. Consequently, the post-installation utility expenses dropped significantly from the initial $71,007 to a more efficient $31,865, marking a noteworthy decrease in operational expenses for the establishment. This reduction highlighted the tangible benefits and enhanced financial efficiency resulting from Intelli-Hood’s implementation.

Radisson Blu – Abu Dhabi achieved an impressive ROI of 1.8 years, underscoring substantial cost savings and operational advantages stemming from their investment in Intelli-Hood. This installation led to a remarkable 55% drop in operational expenses, bolstering the hotel’s financial sustainability and profitability. Additionally, the enhanced energy efficiency reduced carbon dioxide emissions by 898,420 lbs. annually, significantly shrinking the hotel’s overall carbon footprint.

The hotel’s commercial kitchens achieved an optimized average fan speed of 63%, ensuring a harmonized ventilation system aligned with cooking activities. The graph below showcases the fluctuations in fan speed based on cooking demand, depicting the system’s adaptability. This meticulous synchronization significantly contributed to enhancing energy efficiency and cost-effectiveness in the kitchen’s operation, representing a more streamlined and economical approach.

Conclusion

Intelli-Hood® implementation at Radisson Blu – Abu Dhabi yielded a reduction in utility costs, operational expenses, and overall CO2 emissions. This installation of the DCKV system emerged as a valuable investment, optimizing kitchen performance and significantly enhancing energy efficiency.

Download the full case study or contact us today to learn more about Intelli-Hood® and the benefit of kitchen hood controls.