Overview

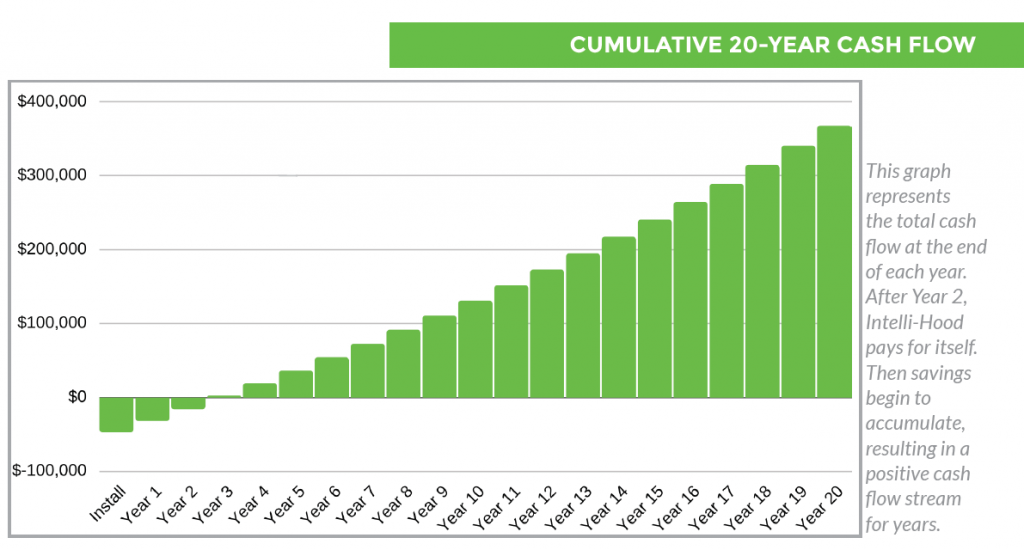

This case study reveals the continued saving results for a specific Culver’s location. The study shows an Intelli-Hood® installation after nearly 20 years of use before upgrading, to continue the restaurant’s operational savings.

The Intelli-Hood® system controls the ventilation fan speed, depending on the current conditions of the kitchen hoods. Temperature and optic sensors are used to detect heat and steam, and these sensors will change the fan speed accordingly. The owners of this Culver’s location saw the benefit in continuing their use of Intelli-Hood®. This fast-food restaurant chain’s main goals were to continue to decrease their spending on utility costs and their operating expenses.

Results

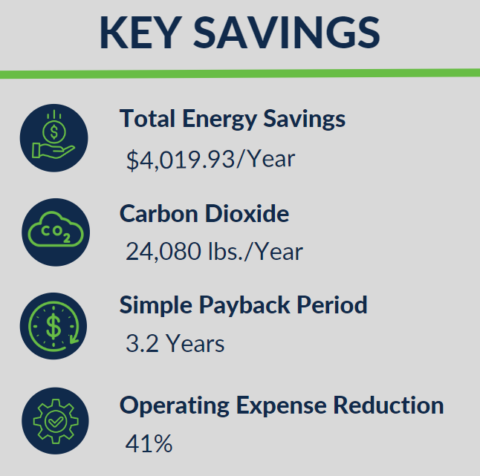

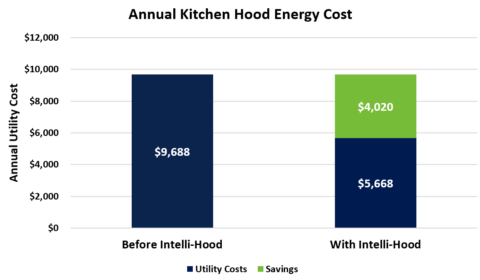

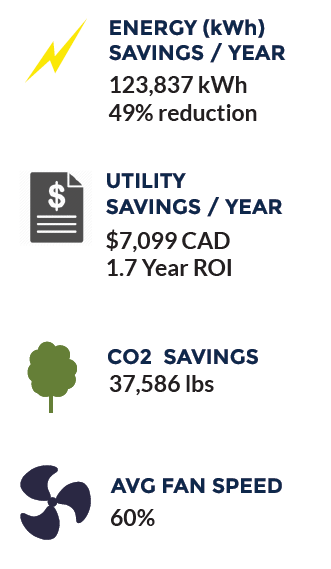

Figure A depicts the customer’s annual energy costs as compared to their net energy costs. After installing Intelli-Hood®, this Culver’s location operates at $5,668 on average for their utility costs. That’s a $4,020 annual savings.

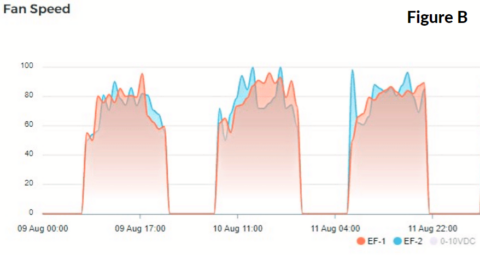

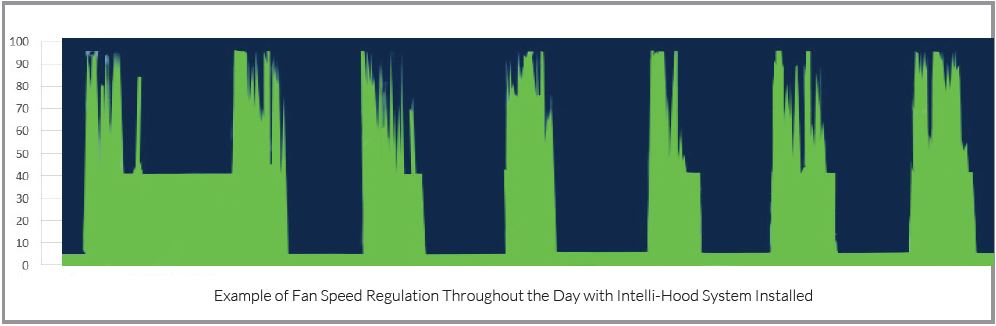

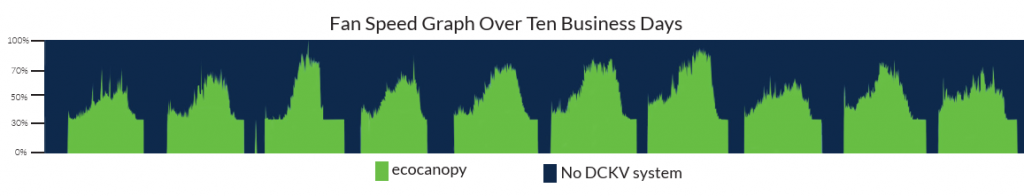

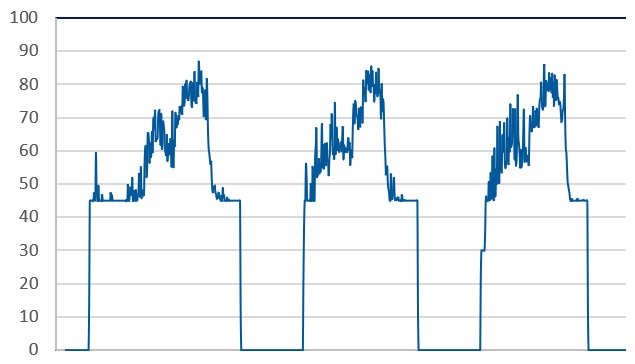

The chart on the right, Figure B, shows the average fan speed for two exhaust fans over the course of three days. The dips in the chart represent times when the fans are not running, and the spikes represent when the fans are operating. The fan speed varies slightly which means the fans are running more efficiently. The average fan speed for these exhausts was 65%.

Download the full case study or contact us today to learn more about Intelli-Hood® and the benefit of kitchen hood controls.