CONTEXT

Like the majority of colleges and universities without kitchen demand control ventilation (DCV) in their dining halls, Hiram College was using inefficient hood fans to cool down their kitchens and to keep employees safe. Running at 100% capacity without any actual cooking occurring, the hood exhaust fans were wasting energy and pushing the meter higher and higher. As a consequence, Hiram experienced expensive utility bills. Below is the operation information for the kitchens:

- Total motor power: 12. HP

- Daily operating hours: 17

- Days per week: 7

- Weeks per year: 52

- Cost per kilowatt hour: $.09

- Climate zone: 5

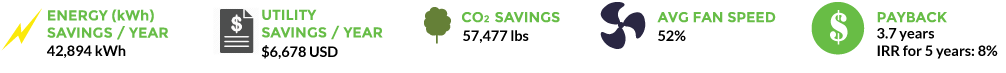

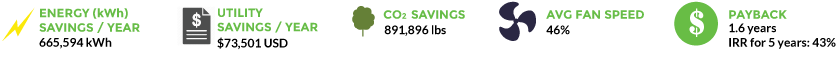

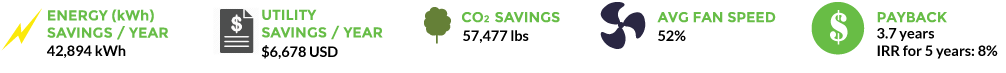

RESULTS

Hiram pursued Brewer-Garrett (BG), a performance contractor for energy efficiency, to consult them in energy efficiency upgrades. BG evaluated their kitchens and cafeterias to identify four areas with high energy consumption. BG recommended four Energy Conservation Measures (ECMs) for these spaces, all of which fell into their 15-year ROI program. Having seen successful ROI performance with Intelli-Hood® kitchen hood controls in previous projects, BG included the technology as 1 of 4 ECMs for Hiram.

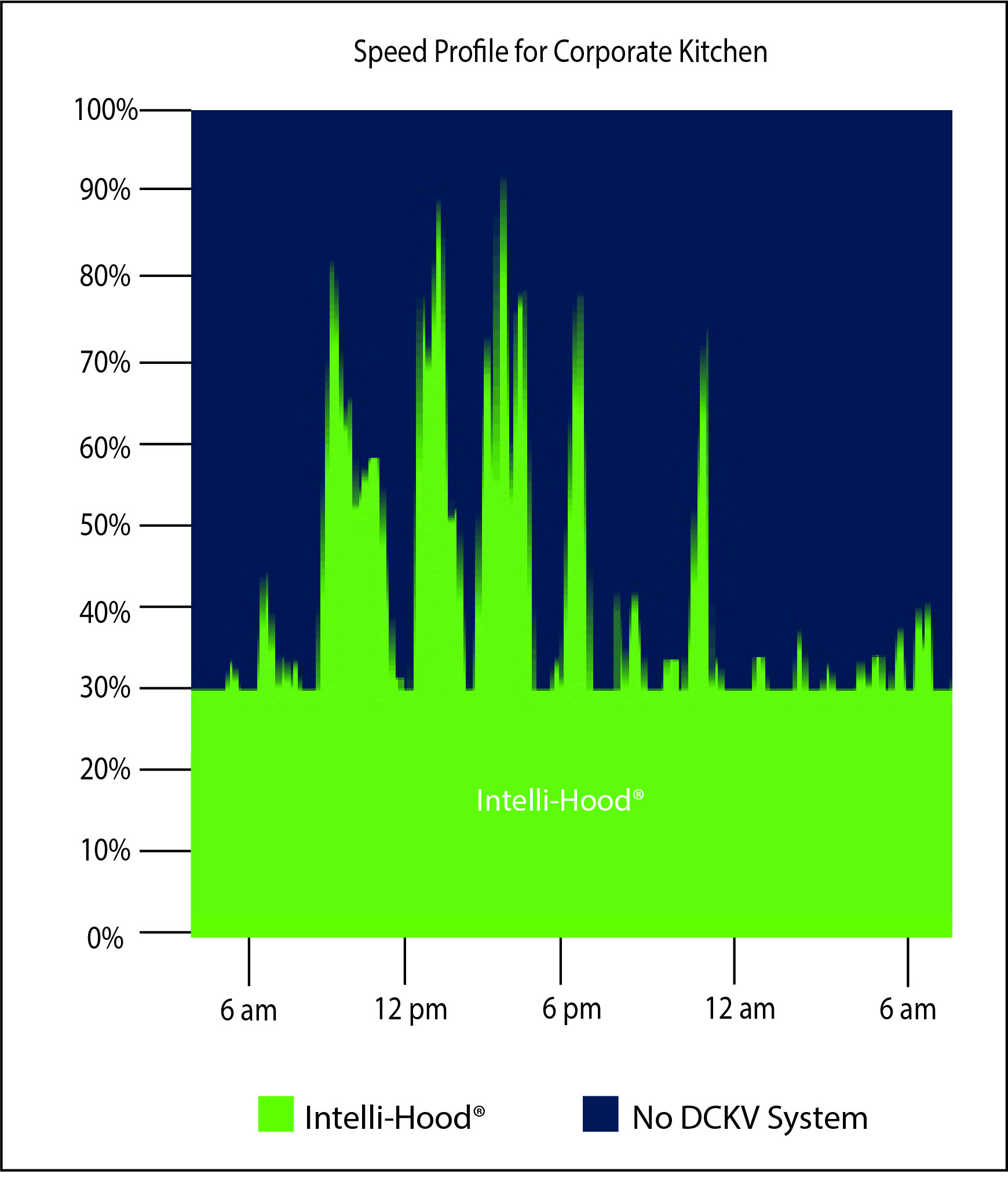

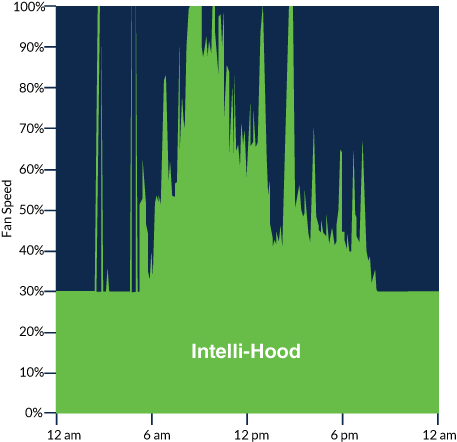

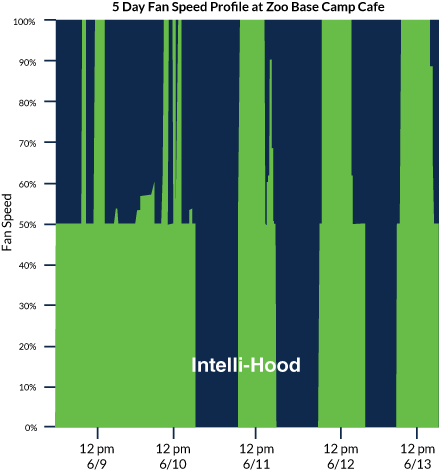

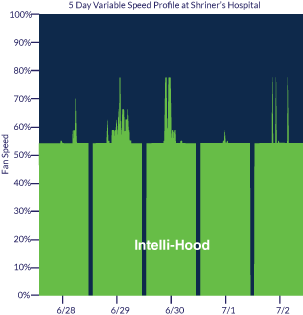

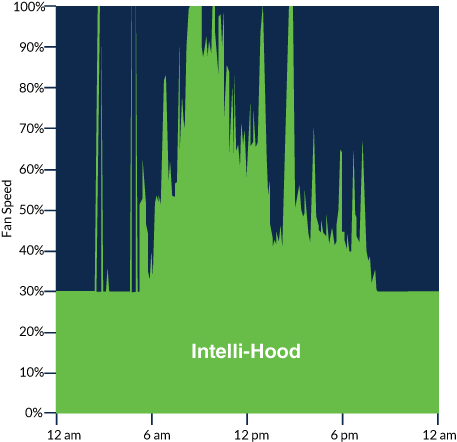

The following is a typical one-day variable fan speed graph using Intelli-Hood®:

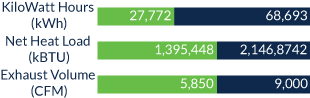

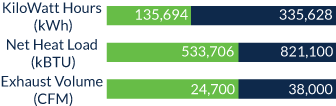

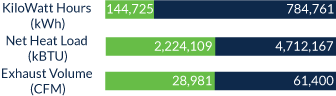

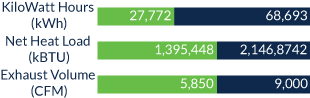

Here is a before (navy) and after (green) reductions in kilowatt hours, heat load and exhaust volume:

The Brewer-Garrett team commented on their impression of Intelli-Hood® and working with Melink:

“You guys have the optimal product for smoke sensing. The cooking sensing technology identifies heat and/or smoke more accurately than other manufacturers. Melink also provides a very thorough turnkey solution, which was very helpful.”

– Eric Betz, Brewer-Garrett, electrical engineering manager

“We appreciate the fast turnaround and positive purchase experience. Also, the Melink installers were courteous and knowledgeable. All Melink personnel were readily accessible and eager to help when called. As far as the system itself, it is well thought-out and high quality. The display is easy to read and use. Also, I like the ability for Melink to remotely monitor and fine tune with their Remote Access service.”

– Jon Erdmann, Brewer-Garrett, senior project manager

COULD INTELLI-HOOD® BE A FIT FOR MY PROJECT?

Are you curious how much energy Intelli-Hood® could save within your commercial or industrial kitchens? Submit an energy savings estimate request form at the bottom of our Intelli-Hood® page to get started.