HVAC Troubleshooting

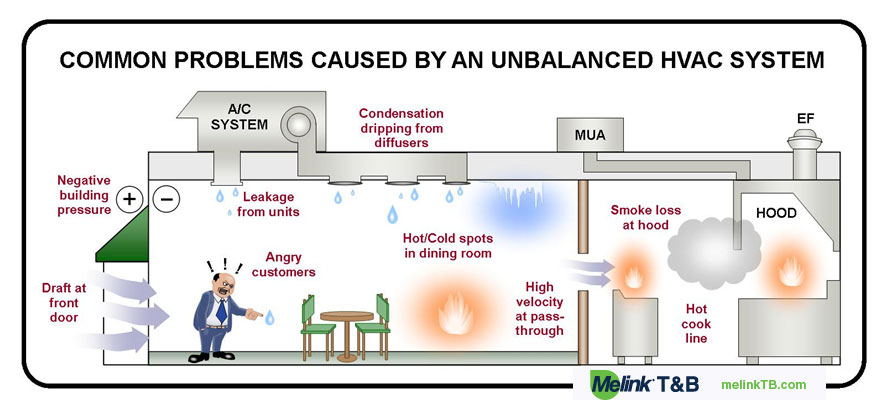

Have you identified that your facility is experiencing a potential air balance problem? You might be experiencing hard to open doors, uncomfortable temperatures, poor smoke capture, odors, drafty areas, or any combination of the other common sick building symptoms. The inevitable question now is, “Who can resolve this best?” Bringing in your facility’s mechanical contractor may be your first instinct but troubleshooting with your onsite managers is actually the best place to start. Work through the following questions with your facility’s day-to-day manager:

1. Is the equipment running?

As basic as this may come across, it is absolutely crucial to check if all HVAC equipment is operating. Check grilles to see if air is being blown out or sucked in. Check roof equipment, can you hear the fans from the RTU, MUA, or EF units spinning? Have the manager record and communicate findings.

2. Check the Thermostats

Navigate to the wall mounted thermostats and ensure they have the proper set points. Often, a thermostat is installed and connected to the system and then left alone. When this occurs the thermostat is left at factory settings which is often set at a random temperature. Your staff can follow the directions on this thermostat to program it for the desired temperatures. As well, check the thermostats for “Fan ON.”

3. Check the Circuit Breakers

Check indoor and outdoor circuit breakers. Observe tripped or “Off” breakers. DO NOT flip the breaker on. If tripped or left off, there’s likely a reason for it and you don’t want to risk frying the electrical systems. We recommend calling an electrician for this type of deficiency.

Armed with your findings from these simple tests, you can save some money with a Do-It-Yourself fix. It’s possible that the journey back to a healthy building ends here. But if the problem persists, it’s time for the level of technical know-how. Call the mechanical contractor. With your observations to these preliminary steps above, you can approach your mechanical contractor with information that will help them to better understand your situation and get you closer to achieving a healthy building.