When a customer is first debating if Demand Control Kitchen Ventilation (DCKV) is right for their facility, there are multiple questions that come to mind. What is a good application for DCKV? What does it cost versus the lifetime payback? Does it actually slow fans down that much? What is the ability for service in the future?

All of these are valid questions. The most important thing is to partner with a company that works with your team to evaluate and determine what solution is best at the onset of reviewing the opportunity. In order to answer the above questions, the DCKV provider should be asking you the following at minimum:

- What is the size of the hood(s) (Length X Width)?

- What is the schedule of the exhaust fans, do they only run 8hrs/day, 12hrs, 24hrs?

- What kind of equipment is underneath the hoods?

- What are current utility rates for your area of the country?

- Is there dedicated supply air to the kitchen space?

With this information the DCKV Manufacturer should be able to provide some advice.

What is a good application?

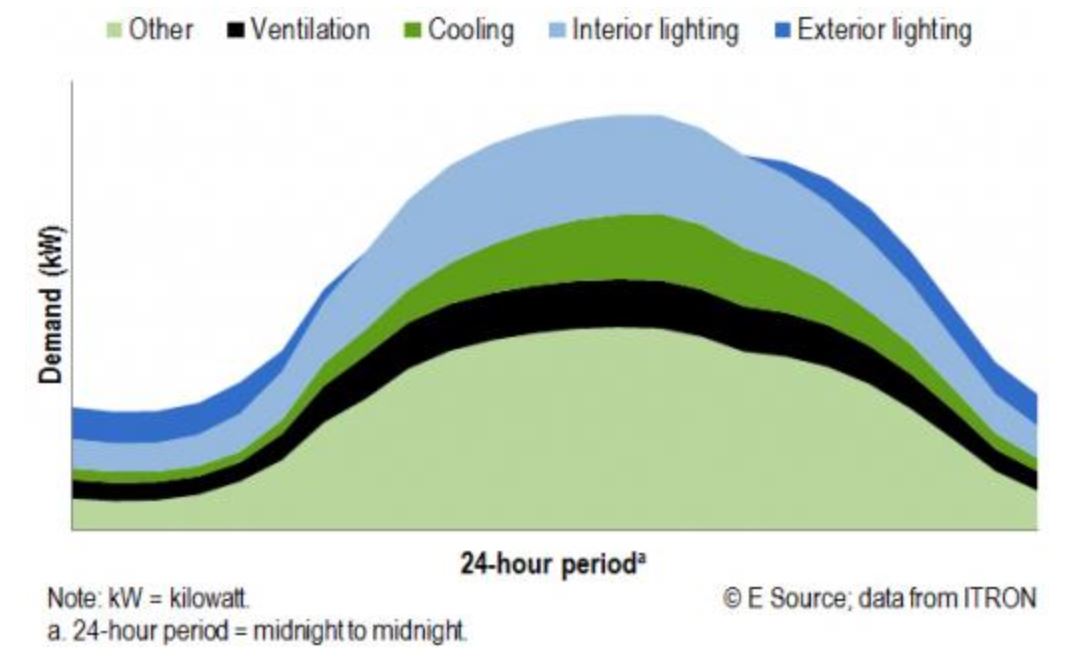

Four primary factors play a role in this answer. They include: utility rates, total fan horsepower (Exhaust + Supply), exhaust fan run hours and your geographic location.

The total horsepower is self-explanatory. The greater the HP the larger available savings. However, lower horsepower may not disqualify an application. If there is a total of 5hp between exhaust and supply, operating longer than 12hrs/day, with moderate utility rates of at least $0.08/kWh, DCKV systems can be a feasible savings opportunity.

Fan operating hours additionally play a role based on the savings, the longer the operations the greater savings. This type of savings can be compounded depending on the geographic location as significant conditioned air savings can be recognized.

What does it a system cost versus the lifetime payback?

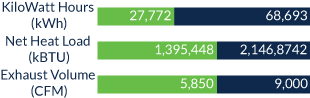

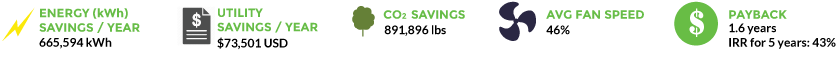

The cost of a system will vary based on the complexity as well as the selected technology. Two options are a temp only based system or one that incorporates additional optic sensors. Although a temp only based system may cost less, it is important to evaluate savings over the lifetime of equipment compared to a system that incorporates optics.

Assume a 12-year life cycle of equipment. For the sake of this discussion, we will evaluate the following scenario:

- Single Hood (20ft long) – 24hr Fan Operation

- 5hp Exhaust (5000cfm) – $0.10kWh

- 3hp Supply – $1.02therm

| Cost | Avg. Run Speed | Annual Savings | Simple Payback | Lifetime Savings (12yrs) | |

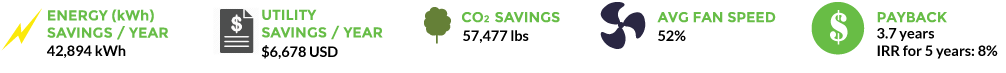

| Temp – Only | $7,000 | 80.5% | $3,502 | 2.0 yrs | $42,024 |

| Optics Based System | $16,000 | 58% | $7,865 | 2.0 yrs | $94,380 |

As seen above the lifetime savings of an optic based system is greater than twice the amount of a temp-only based system. It is important for a DCKV partner to offer a solution best for the customer’s needs, perhaps a blended system would provide the largest amount of savings. For example, perhaps on a larger kitchen, there is significant savings opportunities for one or two of the hoods. However, another single hood has only a single pizza oven underneath, this is when it is important to partner with a manufacturer who has technologies that will maximize savings, such as auto-temp spans and scalability of their system.

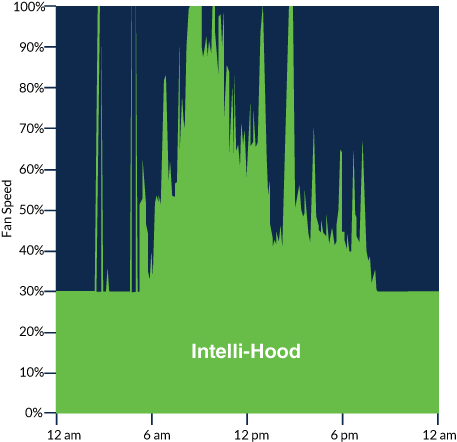

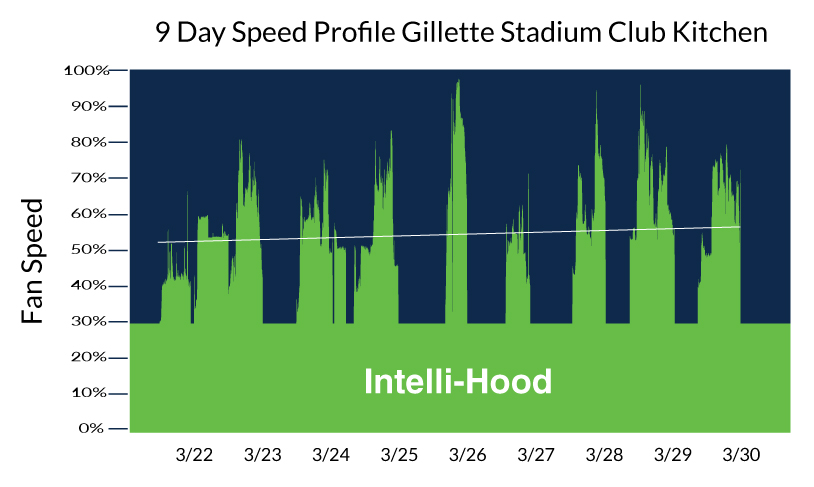

Does it actually slow fans down that much?

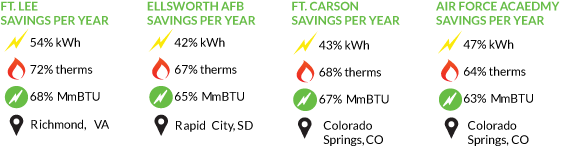

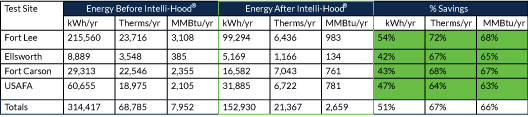

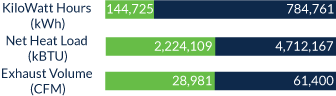

In the savings example above there is a significant disparity between the average runs speeds of a Temp Only based system and that of a system including optics. When reviewing and selecting a DCKV system, it is important to have proven data of performance. Look for manufacturers that have case studies for their technologies, and significant volumes of measurement and verification. Every market sector is different regarding a 24hr average run speed. As a buyer do not hesitate to ask for examples of performance for your market being evaluated. You can also utilize third party publications such as Demand Ventilation in Commercial Kitchens An Emerging Technology Case Study, written by Fisher Nickel, Inc found here.

What is the ability for service this in the future?

One final important aspect to consider is what happens post installation. Commitment from a manufacturer to service over the lifetime of a system is very important. Does your DCKV partner go beyond the standard warranty? Certain manufacturers offer 24hr engineering technical service. Do they have a service network of technicians available to visit your site if needed? Another consideration is where would replacement parts be purchased from. Some manufacturers have components manufactured outside the United States which can delay delivery and in return create a headache for you to provide consistent service to your customers.

Another important focus on the future would be, what is the adaptability of the system? Everyone has seen a kitchen space eventually be remodeled and cooking equipment is swapped out for a new concept. Perhaps there is increased heat from this equipment change, so can the originally selected system adapt to this change? Certain manufacturers have temperature probes that area initially calibrated at startup based on initial equipment. On the other hand, Melink Corporation’s Intelli-Hood, offers an Auto-Temp span, that self-calibrates, and spans based on trends of continuous data points and monitoring therefore, an equipment change resulting in an increase or decrease in heat load will be recognized and self-adjusted for maximum savings.

How to decide what works for you.

In closing, there are many important variables to consider when selecting a product including DCKV. To some, upfront cost is a primary concern, and to many other end users the most important may be what happens over the life of the system. “Will the manufacturer provide me support?” and more importantly “How much will this save me over time?” Many of us are always saving for our retirement, perhaps now is the time to invest in the savings that are available within your kitchen. Personally, I would love to save double that over a lifetime of a system for a product with the same initial payback.