Customer Service Excellence is not only our responsibility, it is the cornerstone of our values at Melink. Since 1987, we have made a conscious effort to make the customer our sole focus each and every day, working to create the absolute best customer experience possible.

This year, in an effort to provide a greater experience for our Test & Balance customers, we restructured our internal account teams. Our decision to revamp our customer service team’s layout was in response to our ever-growing business, and the continually changing nature of what it means to provide a first-class experience. We choose not to be complacent, but rather question daily whether we are utilizing the most efficient customer service tactics in executing our goals and serving customer’s needs.

The new teams are made up of a dynamic group of skillsets to ensure a well-rounded support system, with the customer as the center focus. There is an Account Manager that acts as the point-person in daily communications; an Account Coordinator or Specialist who works directly with customer site contacts to effectively and efficiently schedule our National Network; and an Account Engineer offering specialized technical support for their team’s customers.

We even restructured our office space and customized our email system to provide a more cohesive and resourceful team environment. By rearranging our internal office space, our team members can better communicate proactively and at the speed of business. By providing account-specific email addresses, our customers have the comfort of knowing they are communicating directly with a dedicated team focused on their needs. By scheduling our National Network more effectively, we increase productivity and meet our customer’s needs in a timely and efficient manner.

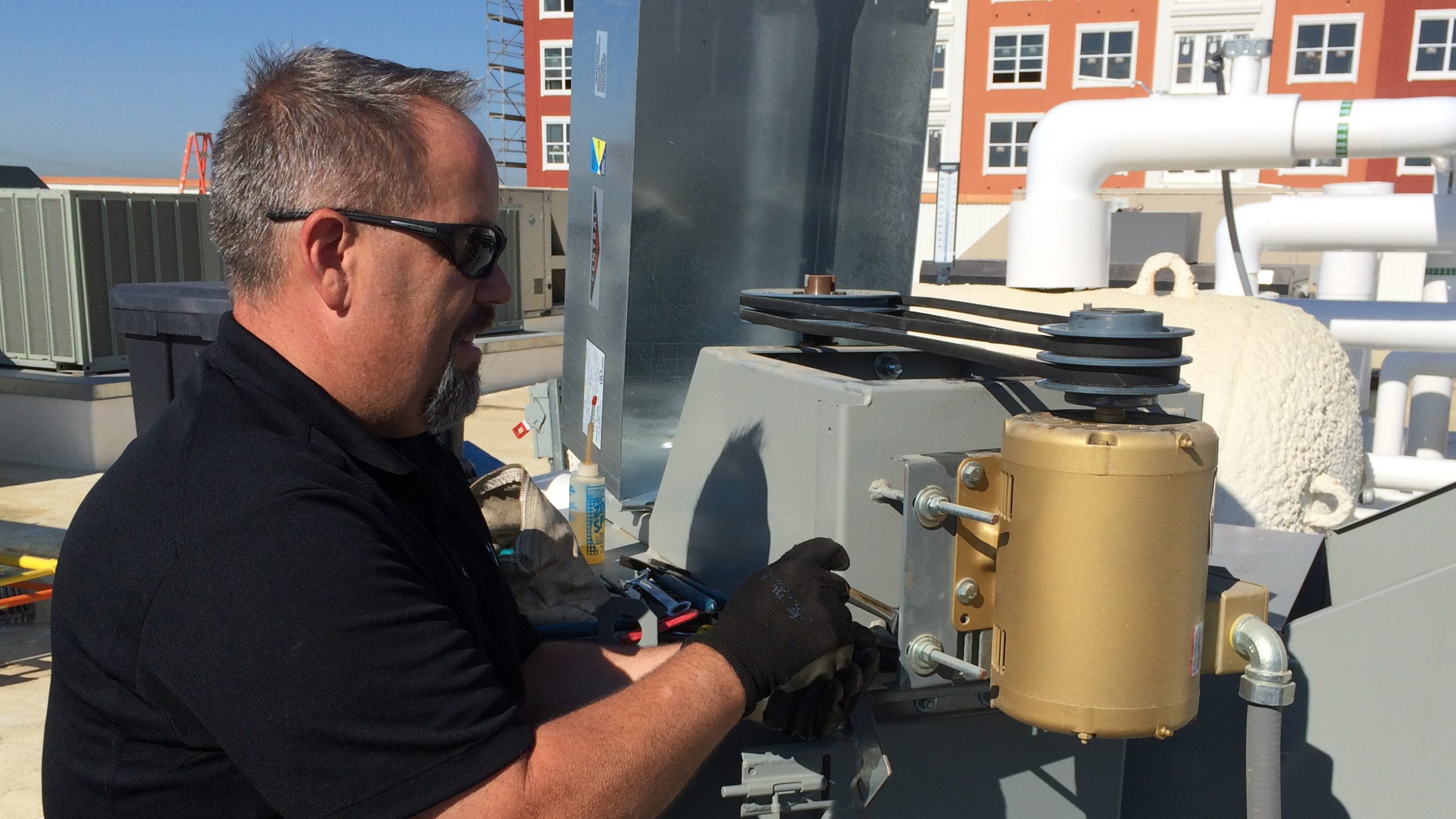

To most, our Test & Balance division is known for providing first-class HVAC services. We go beyond what others in the industry do. We offer more than just a balance – a hands-on support system providing a full customer service experience from order to invoice!