Climate change has been a hot topic recently, and higher education is taking note and taking action. While hundreds of schools have already made pledges to increase sustainability across their campus, 13 schools are taking the lead and taking it a step farther. At this year’s 2018 Higher Education Climate Leadership Summit, 13 North American research universities launched the University Climate Change Coalition, or UC3, a group committed to implementing green initiatives into their own campuses and leveraging their research and experience to help others do the same. For over a decade, these universities have been researching innovative ways to reduce energy consumption, and educating students on how to combat climate challenges that are quickly approaching, but now they taking it a step further to spread this expertise to accelerate change through all of higher education.

As the first school listed on the Campus Carbon Neutrality commitment, Cornell University paved the way. They have made continual efforts to implement Energy Conservation Initiatives (ECI), committing $33M towards ECI’s over a recent 5-year period. The Ohio State University established goals to be carbon neutral by 2050 and to reduce total campus building energy consumption by 25%. Both of these schools have found ways to lessen their carbon footprint by implementing various sustainability practices and products campus wide. Reducing energy use in existing buildings have been an ongoing initiative by both universities focusing on modernizing building envelopes, implementation of building automation and control systems, heat recovery and lighting systems. Cornell states projects they’ve implemented to date have had a return on investment of five to seven years.

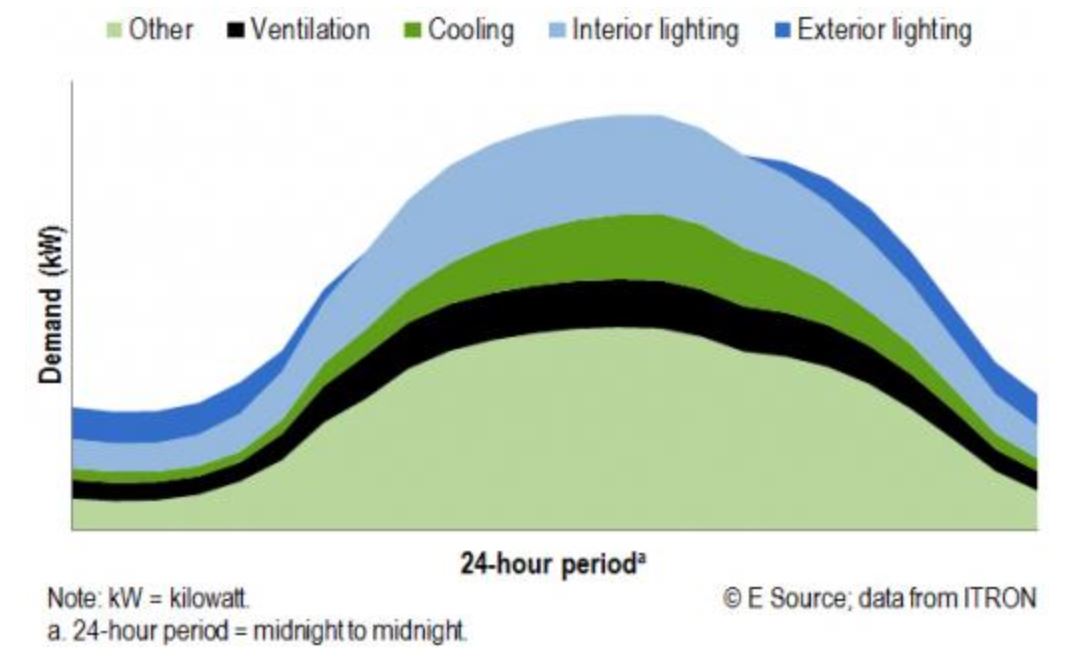

A place that can often be overlooked, but has a great impact, is the ventilation system in campus kitchens. With the demand of long hours to accommodate various student schedules, and high volume because of the dense population, campus kitchens tend to run a majority of the day. Depending where the university is located, various local and state codes may require fans to operate 24/7 if the site utilizes gas pilots on kitchen equipment which remain on overnight. The HVAC systems account for 29% of the energy consumption of a food service area, with up to 75% of this load able to be attributed to the commercial kitchen ventilation system.

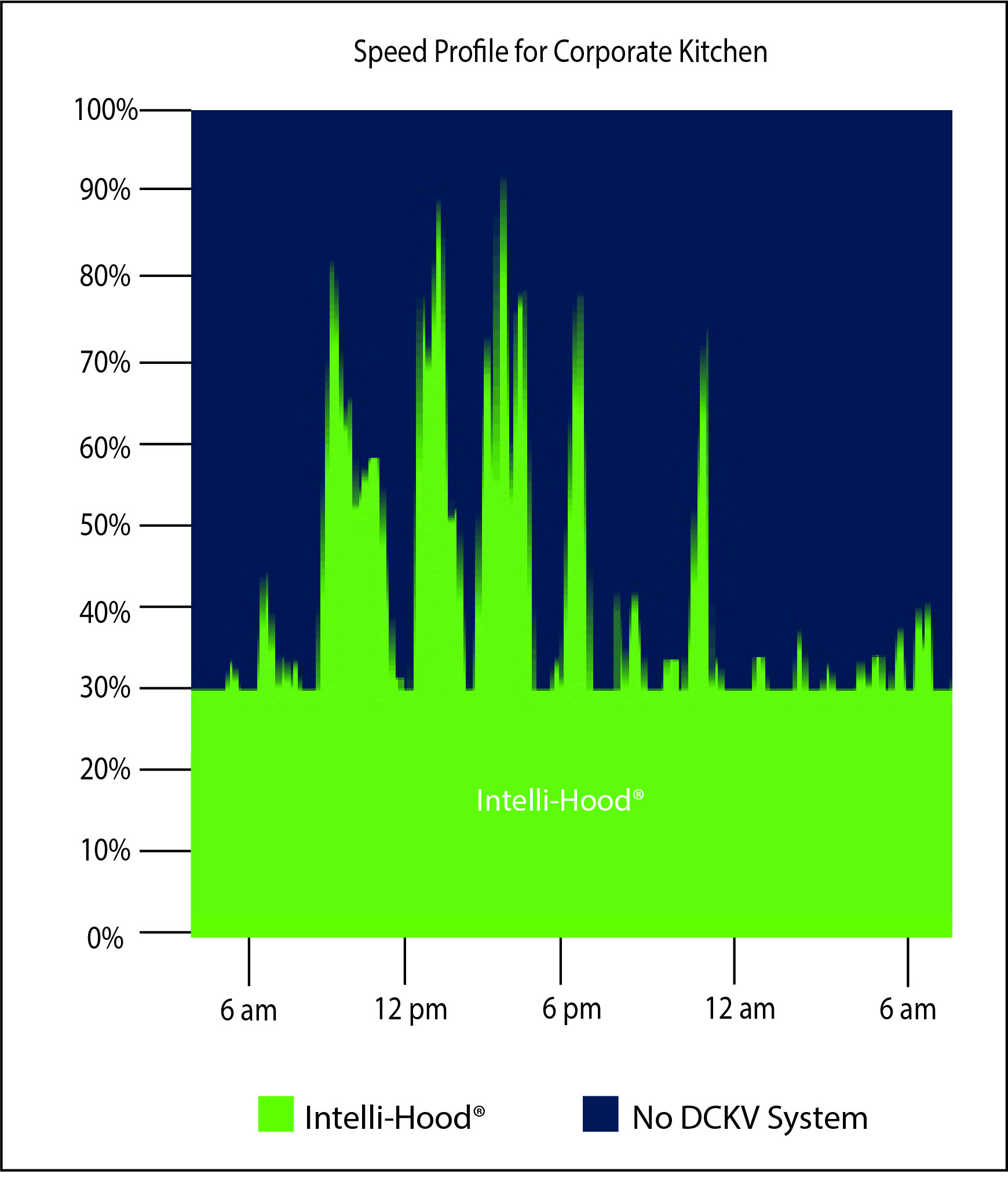

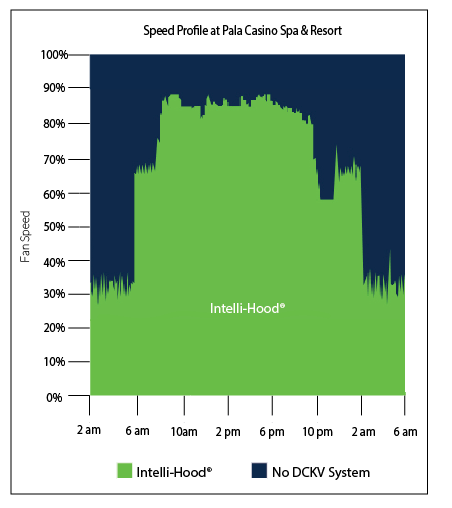

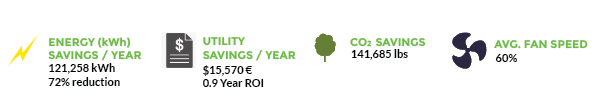

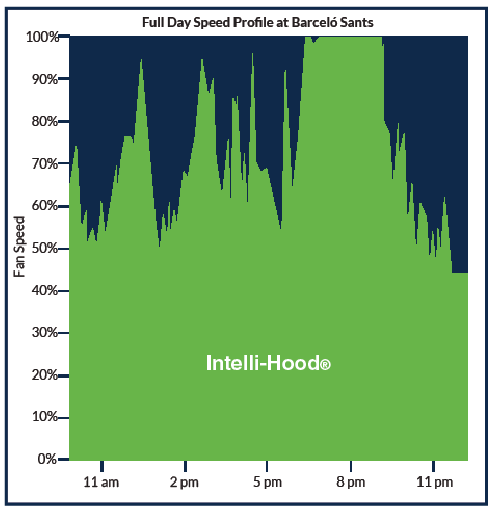

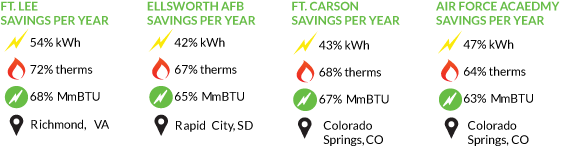

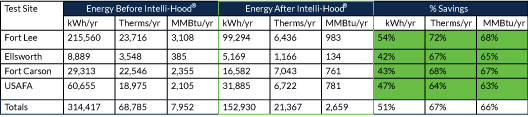

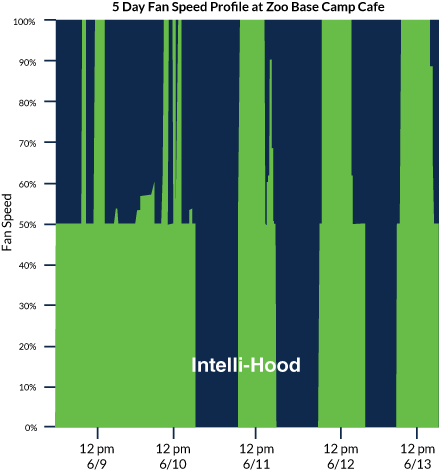

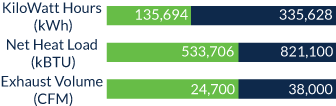

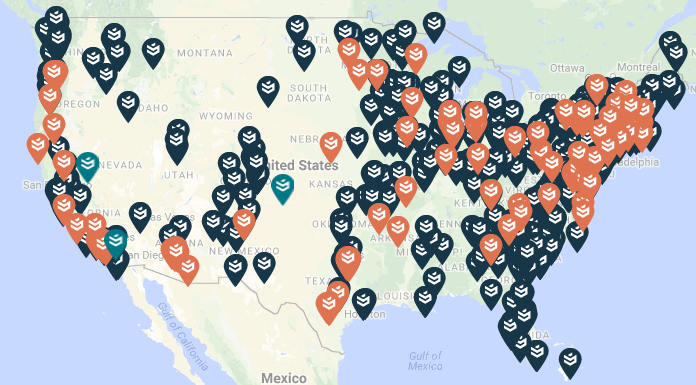

Melink is the innovator of Demand Control Kitchen Ventilation (DCKV) with the Intelli-Hood® system. Both Cornell University and The Ohio State University found the benefit of utilizing dckv systems across a majority of their kitchens. Using Intelli-Hood®, systems operate at a lower overall fans speed average. In an average day, the Melink Intelli-Hood system can recognize up to a 45% reduction in fan speeds equivalent to approximately 83% electrical fan energy savings. Additionally, this reduced operation results in a decrease of load demand of surrounding HVAC equipment providing additional conditioned air savings that can be recognized.