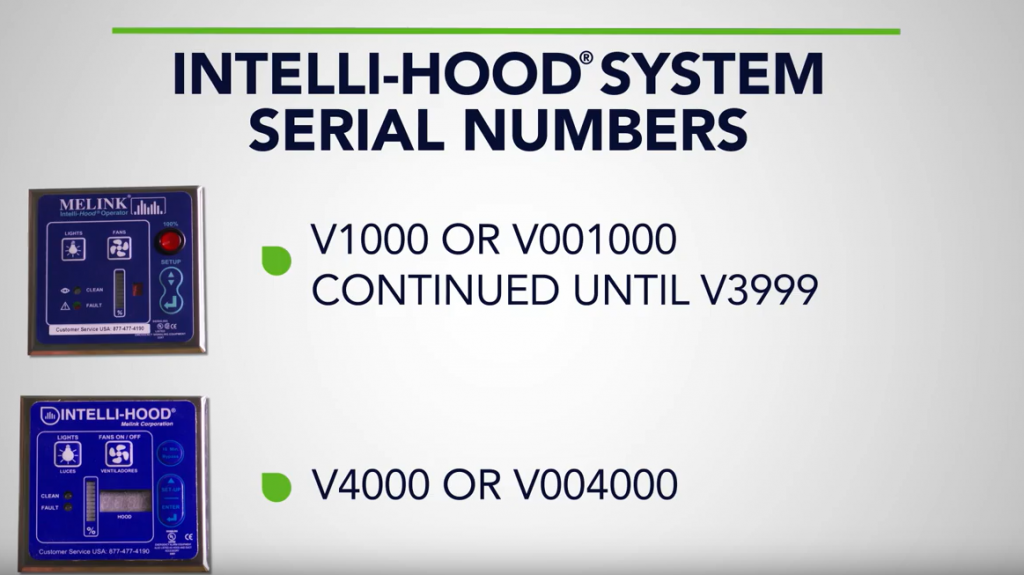

How can a facility manager identify Intelli-Hood systems at his or her various properties? Different systems may be installed, and each system has its own unique reference guide and troubleshooting tips.

Background

Over the years, Melink Corporation has designed and implemented three Intelli-Hood® systems: IH1, IH2 and IH3. Each system has its own specific configurations. While all work on the same basic principles, they DO NOT have the same parts or interfaces.

So how can you determine which system is in your facility? You can determine this by physical attributes and the system’s serial number. Watch our how-to video and consult the steps below…

How to Identify Intelli-Hood Systems

There are three methods to identify your Intelli-Hood system:

Serial Number

The serial number is the absolute best way to identify your system version. On the inside of the system’s panel door, you will see the unit’s serial number. The color of the label may vary, depending on your system. IH1 normally has a white label, whereas IH2 and IH3 have blue labels.

As for the numbers themselves, IH1 systems began with serial V1000 or V001000 and continued until the late V3999 numbers. IH2 serial numbers started at V4000 or V004000 and counted up from there.

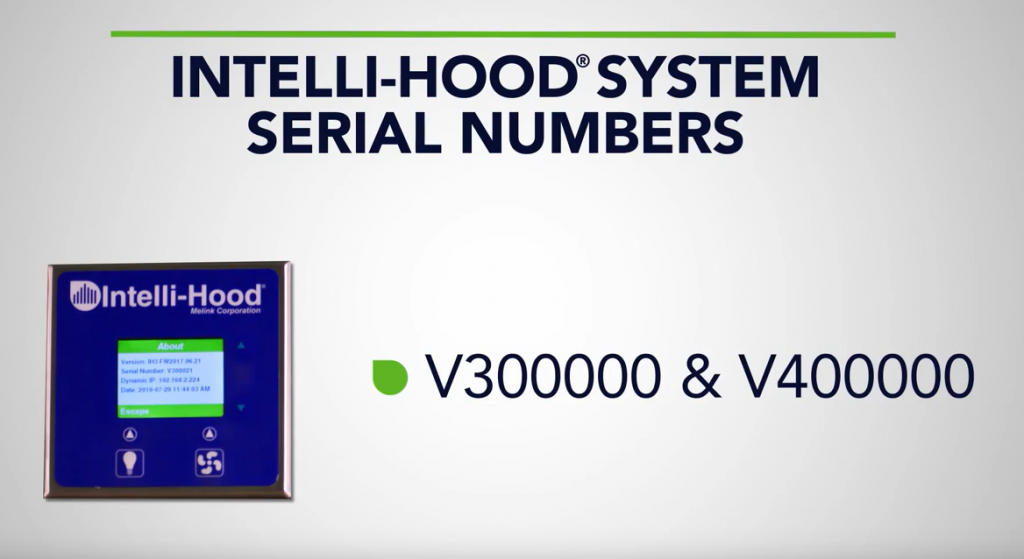

At the beginning of IH3 we changed the starting point slightly and began with V300000. All serial numbers in the V300000 and V400000 are IH3.

Cable Colors

Cable colors are different among systems. If your system has white/grey cables, it is an IH1. If your system has blue cables, it is IH2. Green cables signal IH3.

Touchpads

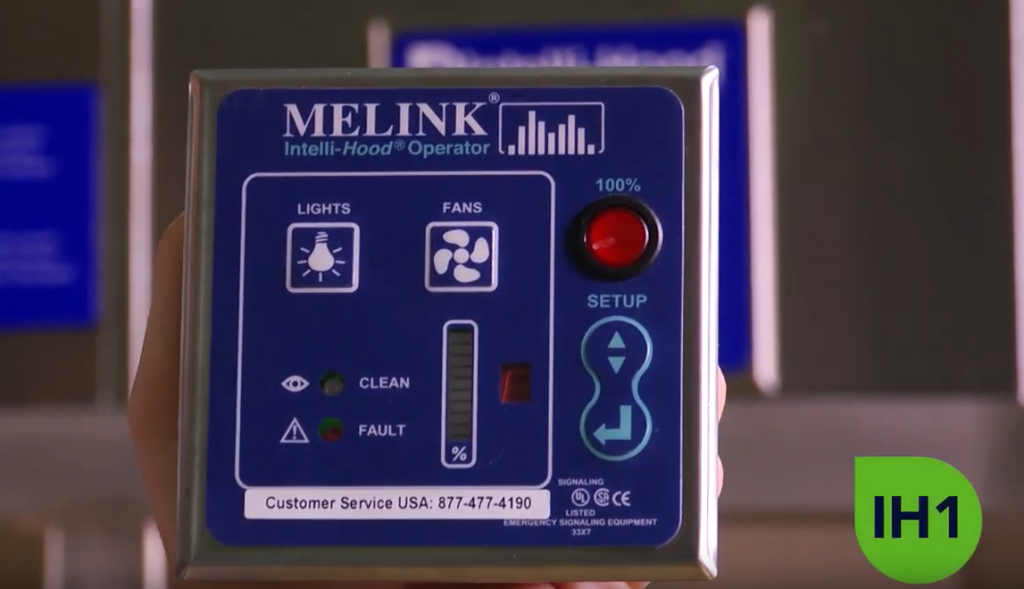

The main touchpad on the kitchen hood can distinguish your system.

IH1 has a single digit “HOOD” display.

IH2 has a four-digit “HOOD” display.

IH3 is our first system with a full LCD display.

Knowing Your System

To accurately troubleshoot system issues and to order replacement parts, you must supply the Melink Technical Team with your system model (IH1, IH2 or IH3). Most issues can be solved over the phone with a facility manager and/or contractor capable of performing the work on site.

If you are purchasing replacement parts and you are not on site, please verify the system model with the site beforehand. If the system model cannot be verified, Melink cannot guarantee the replacement parts are correct. There is a restocking fee for parts ordered in error.

If you cannot determine which system you have, Melink Corp does maintain an internal database. However, we cannot guarantee your facility is in the database. Frequently, restaurant sites change ownership and names. For instance, what was once “Joe’s BBQ” may now be known as “Bob’s BBQ.” If no one has contacted Melink to update the original site name, it will not be searchable in the database.

Access Intelli-Hood reference materials, FAQs, and how-to videos. For advanced troubleshooting, contact Melink Technical Support (available 24 hours a day, 7 days a week) via web request or by calling 877-477-4190.