As the inventors of demand control kitchen ventilation for commercial kitchen systems over 25 years ago, Melink is solely focused on providing maximum energy savings with safe and reliable controls for our customers with our Intelli-Hood® system. Not surprisingly, we’ve learned a lot of things over these years and continuously improve our controls based on lessons learned, industry trends, best practices, technological advances, laboratory and field research. Our industry leader status makes us a ripe target for competitors and naysayers, to which we welcome and enjoy engaging in a healthy debate to advance the usage of demand control kitchen ventilation across the globe. To this end, I would like to address a document produced by a manufacturer and a respected goliath in the kitchen ventilation industry.

*All text in red is directly taken from a Captive-Aire produced document obtained by Melink*

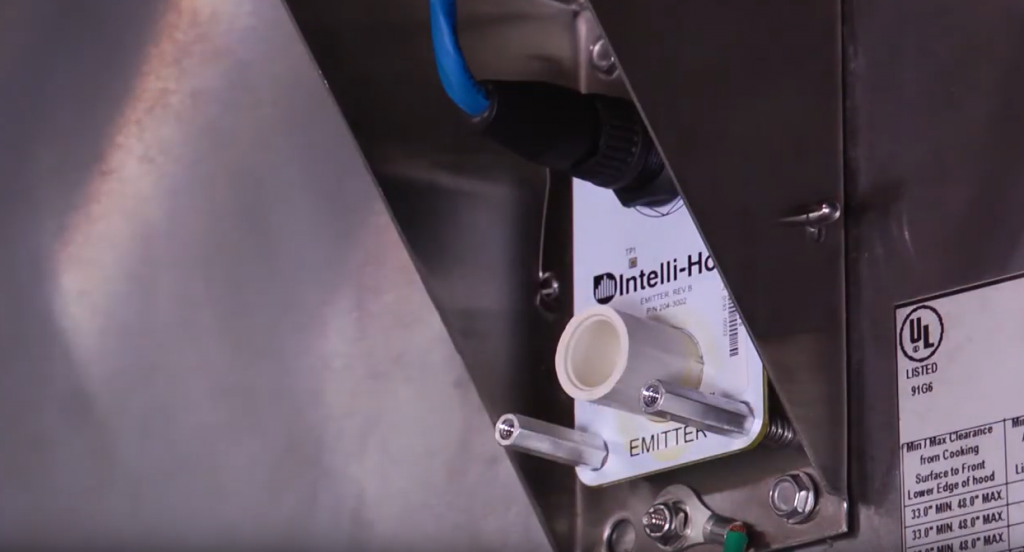

The Captive-Aire Demand Control Kitchen Ventilation (DCKV) system controls the fan speeds based on heat generated from the cooking appliances in comparison to the room temperature. Captive-Aire has done extensive research into the effectiveness and practicality of sensing smoke to override the system and turn on the fans. Melink offers an optic sensor inside the hood, which, if penetrated by smoke, will automatically turn the fans to high speed. This is one of the primary differences between Melink and DCKV.

Melink has performed extensive research over the years into various sensing methods, including space temperate versus hood canopy sensing (delta T) methods, and fallacies discovered in the delta T method is what led us to the patent for utilizing optical sensors in conjunction with heat sensing. Our research uncovered many external factors in the kitchen environment that caused false readings including cross drafts, supply air configurations, door openings and seasonal temperature changes that could trick the system into a cooking response and eliminate energy savings.

Another challenge in the temperature only approach is determining the level of cooking based on these temperature changes alone as the cooking effluent (smoke, steam, etc) often presents itself before a strong thermal plume on the temperature sensor. For example, if you place a cold hamburger patty on a grill the temperature will initially reduce as the heat transfers into the food while creating effluent that must be captured by the hood. Systems reliant upon temperature only are slow to react to this change and you are left with two options; decrease the temperature range of the system so it runs full speed at the slightest presence of heat (diminishing any energy savings), OR don’t effectively capture the effluent in the hood canopy and cause smoke rollout. As we at Melink like to say, “You can’t capture what you can’t see.”

We have found that using an optic sensor to sense smoke is very problematic. When installed inside a greasy exhaust hood, the lens will tend to get caked with grease. This will cause the fans to run at full speed all the time, and therefore eliminate your energy savings. As a result, Melink installs small fans to continuously blow air at the lens to try and avoid grease particles from landing there. This is another component the needs to be maintained and serviced regularly. These optic lenses also require an I/O processor to be wired into the system—this is one more component. If anything happens to the lens, fan, or processor the system will fail. This results in a sustainability issue. Electrical components inside a greasy exhaust hood may not be a sustainable option over the course of several years. The optic sensors/lenses need to be cleaned, and according to the Melink manual, should not be sprayed with hot water or steam by the hood cleaner to avoid damage.

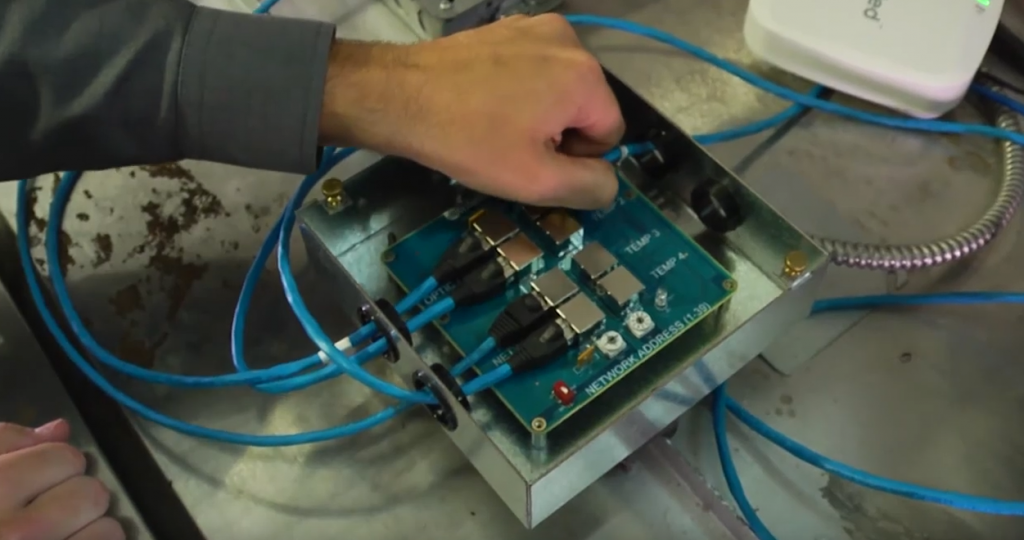

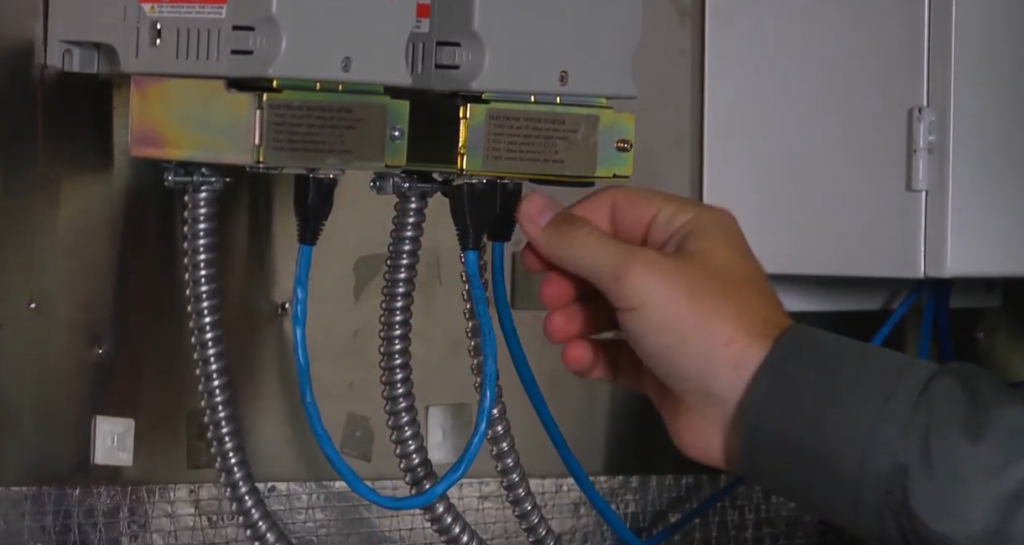

Yes, our system has a brain and it’s called the System Controller (formerly I/O Processor referenced). All demand control kitchen ventilation systems have some sort of controller to interpret the signals coming in and we like to think our brain is pretty special. In fact, unlike most competitor systems that utilize an off the shelf PLC controller we custom design ours for the sole purpose of saving you energy in the kitchen and integrating into your building. Our System Controller is native BACnet (IP), internet ready, 4G wireless capable and has the brainpower to control up to (39) kitchen hoods and (64) exhaust or supply fans.

We do utilize a component called the Air Purge Unit (APU) that contains a 12VDC fan to direct airflow into the optic housing to maintain a positive pressure environment to alleviate grease buildup. However, kitchens can be harsh environments and depending on the appliance type underneath these could benefit from a monthly swipe with a clean cloth if it’s above a high grease producing appliance, but less intensive appliances mean less cleaning. Fortunately, we use that big brain of ours to automatically re-calibrate the optics every day based on cleanliness for optimal performance and if it gets too dirty the system will alert you via the Touchpad or email as to which hood may need cleaned.

Additionally, a typical Melink system costs much more than a Captive-Aire DCKV so the payback period for a Melink system is much longer.

Not necessarily, the formula for the simple payback period is the initial project cost divided by the annual savings to determine at what time the investment breaks even. If a more intelligent system can save 3x the energy of temp-only system, then the simple payback periods are equal. The downside of this metric is the failure to account for the time value of money and consideration of cash inflows beyond the payback period. It’s important to look past first cost and take into account the full savings yielded over the life of the system and perform life cycle cost analysis.

For example:

Temp-Only System

- First Cost = $5,000

- Annual Savings = $1,500

- Simple Payback Period = 3.3 Years

- Energy Savings over (7) Years = $10,500

- Net Savings: $10,500 – $5,000 = $5,50

Melink Intelli-Hood®

- First Cost = $15,000

- Annual Savings = $4,500

- Simple Payback Period = 3.3 Years

- Energy Savings over (7) Years = $31,500

- Net Savings: $31,500 – $15,000 = $16,500

Over the life of the systems in this example Intelli-Hood® will yield $21,000 in more energy savings vs. the competitor, less the initial capital difference of $10,000 ($15,000 – $5,000) = $11,000 more in

free cash flow. This example does not factor in the time value of money.

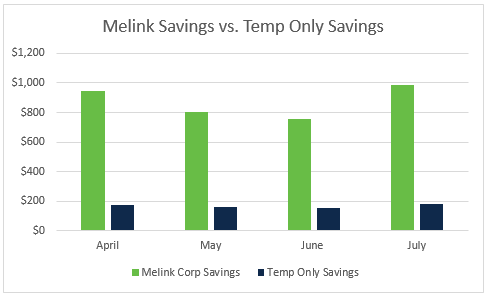

The below data shows the savings difference when a Melink Intelli-Hood® system was installed at a restaurant previously using a temperature only system. The baseline data was provided to the owner by the temp-only hood manufacturer, and we analyzed the electrical and conditioned air savings via our Estimated Savings Report. Once the Intelli-Hood® system was installed we compared the data and found that Intelli-Hood® system yielded 523% more savings than the previous system. Click here to see real IH performance results.

Testing has shown that very sensitive heat sensors are as effective as optic sensors in triggering exhaust fans if heat or smoke is present. If cooking generates smoke, then the cooking process will also generate heat. The heat sensors in the Captive-Aire Demand Control Kitchen Ventilation are easily adjustable as different project and applications may require.

Through our own testing in the lab environment, and more importantly the lab of reality in the commercial kitchen with over 10,000 systems, temperature sensing alone will not allow for a quick response to smoke. Based on our data obtained from an installed temp-only system, the heat sensors appeared to provide no active modulation and acted basically as a two-speed system with an active base speed of 80% and quickly ramping a holding a constant speed of 100% through the day since the appliances were on. Again, without the ability to visually monitor the cooking a temp-only system must be run at much higher minimum speeds as a safety net for capturing effluent. This is a major energy savings penalty.

The heat sensors may be “easily adjustable”; however, this requires human manipulation and functional commissioning. Most often these systems are sent to a mechanical contractor with the instruction to connect the temperature probes to control panel and are left at whatever the default factory setting is. We like humans too but given the chance we like to engineer around potential issues and lack of consistency from one contractor to the next around the world. Thus, we patented another feature dubbed “Auto-Temp Span”, which collects performance data from every sensor in the system at defined intervals and automatically sets the optimal temperature spans for every hood in the system. If the chef decides to change menus, appliances, or a new tenant takes over the space the system will learn these new habits and self-commission for optimal performance. Call it “machine learning”, call it “artificial intelligence”, we call it a good idea that benefits the end-user.

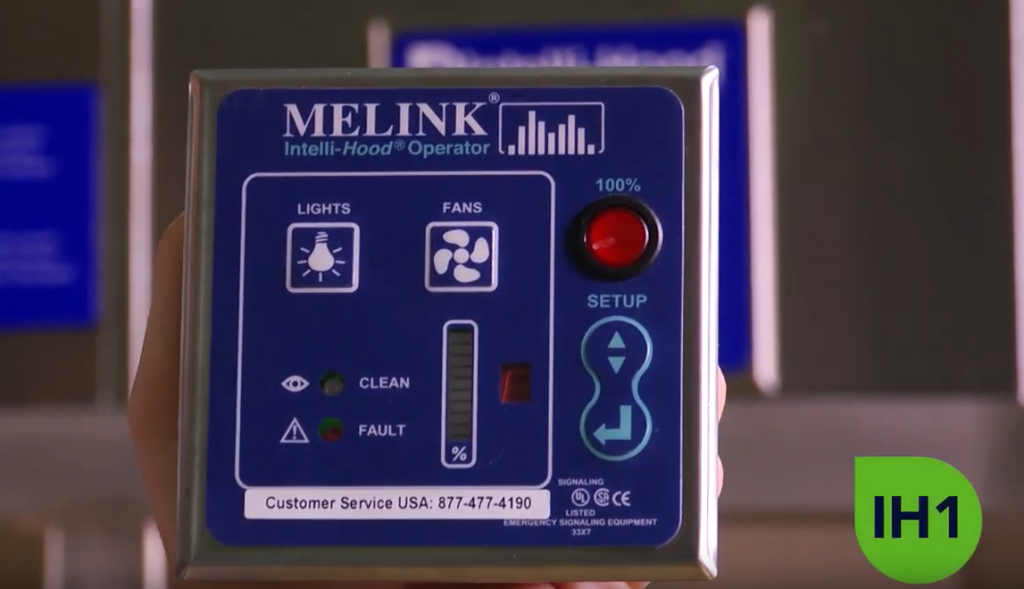

Lastly, the DCKV has a 100% air override button to send the fans into full speed as a safety precaution.

This override button feature is a code requirement for all demand control kitchen ventilation systems; we have one too.

Here are a few additional differences between Captive-Aire DCKV and Melink Intelli-Hood®:

- Captive-Aire DCKV is typically programmed with a “prep mode” feature to allow greater energy savings. This feature will run the exhaust fans at a very low speed

(typically, 20% speed) when the system is first turned on by staff or BAS. This speed is equal to the design differential between exhaust and make-up air. DCKV will run in prep mode until the heat of the appliances necessitates greater exhaust at which point the exhaust and make-up air will both ramp up and cooking mode will commence.

Melink as currently designed runs both make-up air and exhaust at 50% of its design.

- In cooking mode, Captive-Aire designs for a 20% reduction in fan speed during light load cooking times. This reduction is based on extensive research on the topic. Lab testing by The Food Service Technology Center in California has shown that no more than a 20% reduction from a proper design cfm can be made in order to allow the

system to adequately exhaust appliances when in light load. The Melink system allows for a 50% turndown, therefore, in order for that amount of

reduction to work properly, the design cfm would have to be increased so the system still works effectively at a 50% reduction. A lower design cfm with 20% fan speed reduction will be more efficient and save more energy than a higher design cfm with 50% fan speed reduction. Captive-Aire DCKV has the ability to provide a 50% turndown, but we do not recommend this.

From our perspective, this represents nearly a three-speed system with “modes” to make up for the lack of technology, sensors, programming, and algorithms to modulate based on real-time cooking information and optical monitoring, resulting in a loss of energy savings ability. As representative in our data, the temperature spans are typically set so low with these systems, that as soon as any appliances are on, the fans run at an 80% minimum for a very short amount of time and then jump right to 100%. Unfortunately, it’s pretty rare to see any appliance gas valve regulation in commercial kitchens and most appliances are left at nearly full temperature all day independent of actual cooking, which causes temp-only systems to run at or near full speed all day. We’ve also come across several temp-only systems in the field running at 100% speed when the exhaust temperature read 72 and 73 degrees Fahrenheit.

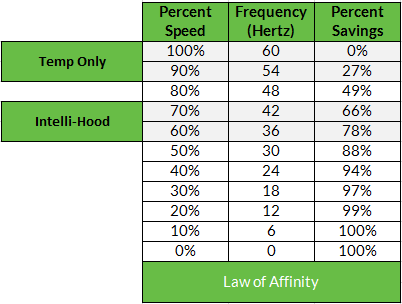

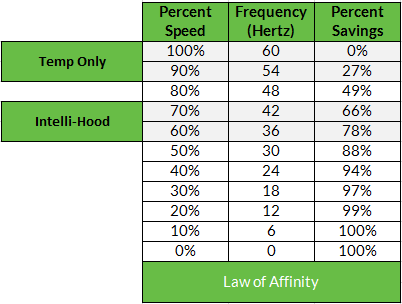

The Melink Intelli-Hood® system is capable of 20-30% minimum speeds as well, but turn-down ratio is a moot point when the rubber meets the road, or when the meat hits the grill in this case. Our default minimum speed is 30%, a 2% electrical energy difference vs 20%, and we actively modulate through the entire speed spectrum to 100% to maximize energy savings. The key to electrical energy savings in motor applications lies in the Law of Affinity (below), which at the top of the fan curve roughly translates to a 10% speed reduction = 25% electrical energy

savings. The key to savings with demand control kitchen ventilation is having the optics to safely and actively modulate at the upper ends of the spectrum during the cooking day to maximize savings near the top of the fan curve between 70-100%.

In addition to electrical energy savings from the motor control, Intelli-Hood® also integrates into the make-up air system to modulate based on the exhaust demand. This modulation provides additional conditioned air savings and can have a significant impact on the payback of the system. The more extreme the outdoor air environment, the greater the opportunity for energy savings in the reduction of the heating or cooling loads. The ratio of savings for conditioned air is 1:1 with fan speed reduction, i.e., a 30% reduction in speeds = 30% reduction in conditioned air.

With nearly 20 states adopting ASHRAE 90.1 2010, or higher, energy standards it’s clear that demand control kitchen ventilation is here to stay and we’re proud to have launched this revolution back in 1989. One of our core values at Melink is Innovation, and we continue day in and day out to develop more advanced commercial kitchen control systems to save our customers valuable money and hopefully make the planet better for our future generations one hood at a time. Feel free to contact us regarding your next kitchen design involving demand control ventilation or if you’re an existing operator of a commercial kitchen looking to save money, we happen to be experts in retrofits as well.